Complete Power Electronics Mastery Guide

Master the art of power conversion and control - from basic rectifiers to advanced AC-AC conversion techniques in modern electronic systems. Your comprehensive journey from fundamentals to cutting-edge applications.

Complete Learning Path - All Power Conversion Types

Navigate through comprehensive coverage of power electronics fundamentals to advanced applications

What is Power Electronics?

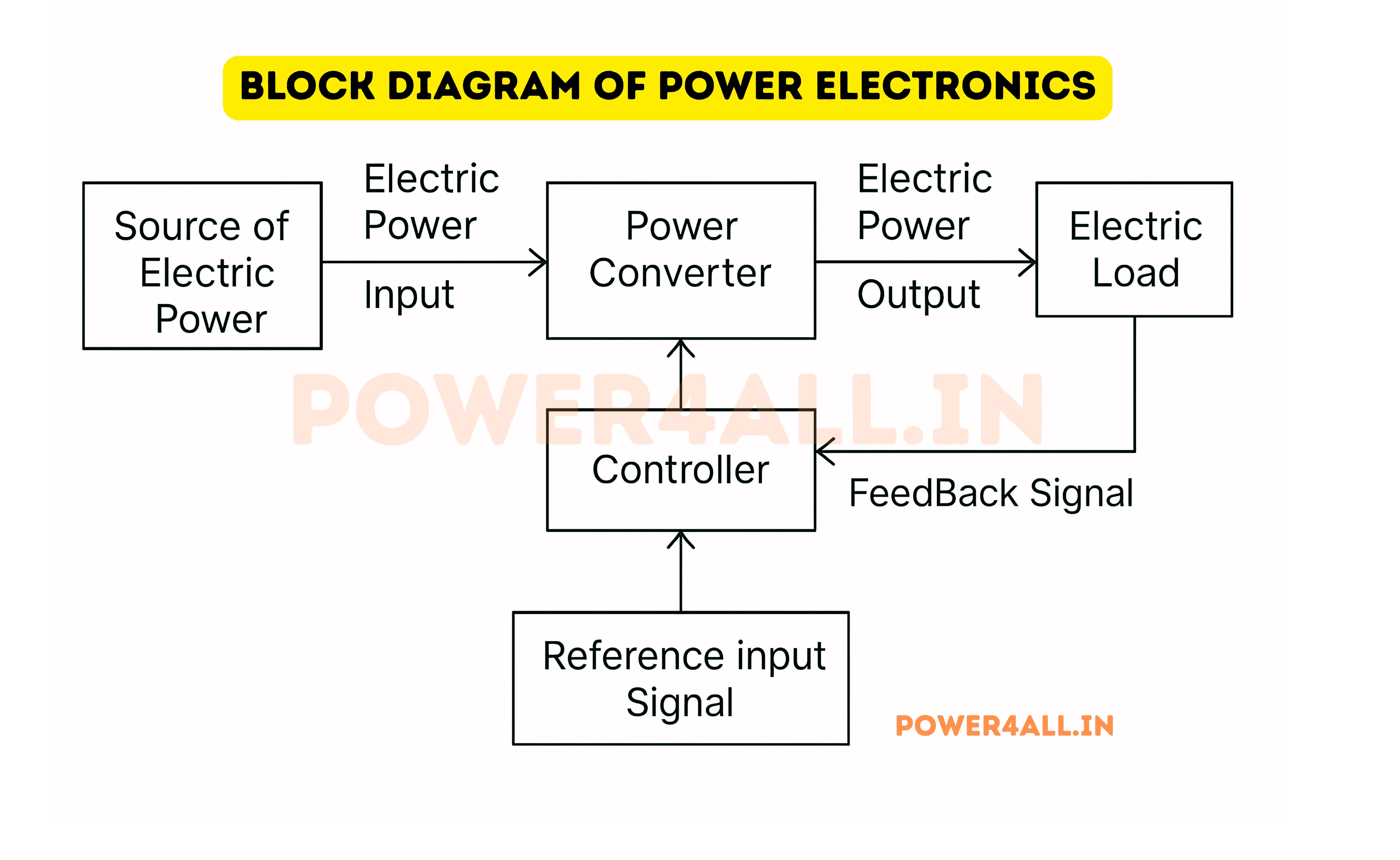

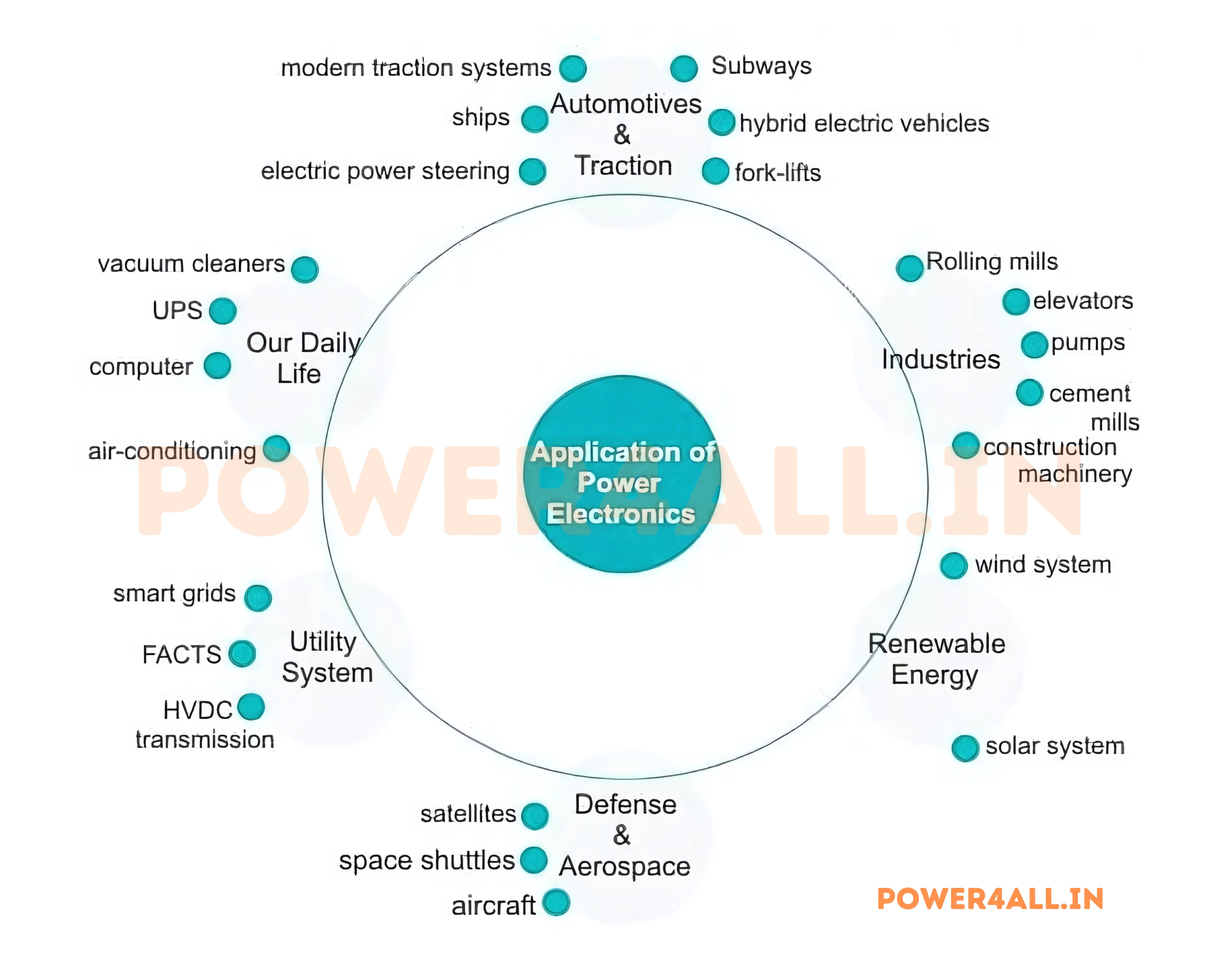

Power electronics is the technology of efficiently converting electrical power from one form to another using electronic devices. It combines electronics, power engineering, and control systems to process and control the flow of electrical energy in applications ranging from smartphone chargers to industrial motor drives and renewable energy systems.

The Power Conversion Process

Think of power electronics as "electrical power transformation". Just as a transformer changes voltage levels, power electronics can change voltage, current, frequency, and even convert between AC and DC with high efficiency.

Everyday Examples You Use Daily

- Phone charger: Converts 120V/230V AC to 5V DC (AC-DC conversion)

- Electric car: Converts battery DC to variable frequency AC for motors (DC-AC)

- Solar inverter: Converts panel DC to grid-synchronized AC (DC-AC)

- Computer power supply: Multiple DC voltages from AC input (AC-DC)

- LED lights: Convert AC to low voltage DC (AC-DC)

- Motor drives: Variable speed control for fans, pumps (AC-AC)

- UPS systems: Battery backup with clean power output

- Laptop adapters: Efficient voltage step-down conversion

Why Power Electronics is Essential

Ultra-High Efficiency

Modern power electronic systems achieve 95-99% efficiency by using fast switching instead of linear control, minimizing energy waste as heat. This translates to significant energy savings - a 1% improvement in efficiency for a 1MW system saves over $8,000 annually in electricity costs.

Precise Control

Electronic switches can turn on/off thousands to millions of times per second (kHz-MHz), enabling precise control of power flow, voltage, current, and frequency with digital accuracy. This enables applications like variable speed motor drives and high-quality audio amplifiers.

Compact & Lightweight

High-frequency switching allows smaller magnetic components (transformers, inductors), making power electronics more compact than traditional linear approaches. Modern phone chargers are 70% smaller than equivalent linear designs while being more efficient.

Reliable & Smart

Solid-state devices have no moving parts, providing reliable operation with built-in protection features like overcurrent, overvoltage, thermal shutdown, and predictive maintenance capabilities using IoT connectivity.

Environmental Benefits

Power electronics enable renewable energy integration, electric vehicle adoption, and efficient motor drives, collectively preventing billions of tons of CO2 emissions annually while supporting the transition to sustainable energy systems.

Economic Impact

The global power electronics market exceeds $50 billion annually with 6.5% growth rate. Variable speed drives alone save 20-50% energy in motor applications, representing over $100 billion in annual energy savings worldwide.

Power Electronics vs Traditional Electronics

| Aspect | Traditional Electronics | Power Electronics | Key Difference | Modern Applications |

|---|---|---|---|---|

| Power Levels | Milliwatts to Watts | Watts to Megawatts | 1000× to 1,000,000× more power handling | From phone chargers to grid-scale systems |

| Primary Function | Signal processing & amplification | Power conversion and control | Information vs Energy handling | Data processing vs Energy management |

| Voltage Levels | 0.8V to 50V typical | 5V to 500kV+ | Much higher voltage operation | HVDC transmission, EV fast charging |

| Current Levels | Microamps to Amps | Amps to Kiloamps | Much higher current handling | Industrial motor drives, welding |

| Efficiency Focus | Performance and speed | Energy efficiency paramount | Power loss minimization critical | Green technology, sustainability |

| Heat Management | Basic thermal design | Advanced cooling systems | Thermal management is crucial | Liquid cooling, thermal monitoring |

| Control Complexity | Analog/Digital processing | Real-time power control | Microsecond response times | AI-based optimization, IoT integration |

η = (P_out / P_in) × 100%

Efficiency is the primary measure of power electronic performance - every 1% improvement saves significant energy and costs

Historical Development

Evolution of Power Electronics Technology

| Era | Key Technology | Major Breakthrough | Efficiency Range | Applications | Market Impact |

|---|---|---|---|---|---|

| 1900-1950 | Mercury Arc Rectifiers | First controllable power devices | 60-75% | DC motor drives, electrochemical processes | Industrial DC power systems foundation |

| 1950-1970 | Thyristors (SCRs), Triacs | Solid-state power control | 75-85% | HVDC transmission, controlled rectifiers | Reliable high-power switching revolution |

| 1970-1990 | Power MOSFETs, BJTs | Fast switching, easy control | 80-90% | Switch-mode power supplies, early VFDs | Personal computer revolution enabler |

| 1990-2010 | IGBTs, Smart Power ICs | High power + fast switching | 90-95% | Variable speed drives, renewable inverters | Energy efficiency revolution, $500B market |

Power Electronics Fundamentals

Understanding power electronics requires grasping fundamental concepts of power conversion, switching techniques, and the behavior of power semiconductor devices under different operating conditions. These principles form the foundation for all power electronic applications, from simple rectifiers to complex grid-tied systems.

The Core Switching Principle

Why Switching Achieves High Efficiency

Power electronics achieves remarkable efficiency by operating switches in either fully ON (saturated) or fully OFF (cut-off) states, minimizing power loss during brief switching transitions.

Power Loss Comparison in Real Applications

- Linear regulation (old method): 50-70% efficiency, high heat generation

- Switching regulation (modern): 85-98% efficiency, minimal heat

- Key insight: Switching minimizes simultaneous high voltage AND current

- Energy saved: 20-40% less power waste as heat

- Cost impact: Smaller cooling systems, higher reliability

- Environmental benefit: Reduced electricity consumption

P_loss = V_switch × I_switch

Power loss minimized when either V≈0 (ON) or I≈0 (OFF)

| Switching Parameter | Typical Range | Impact on Efficiency | Modern Trend |

|---|---|---|---|

| Switching Frequency | 1kHz - 1MHz | Higher freq = smaller components | 100kHz-1MHz+ with WBG |

| Rise/Fall Time | 10ns - 10μs | Faster = lower switching loss | Sub-ns with GaN devices |

| On-State Resistance | 1mΩ - 1Ω | Lower R = lower conduction loss | Ultra-low R with parallel devices |

| Dead Time | 50ns - 2μs | Prevents shoot-through | Adaptive dead-time control |

Advanced Switching Techniques

Soft Switching: Zero-voltage (ZVS) or zero-current (ZCS) switching

Benefits: Reduced EMI, lower stress, higher efficiency

Applications: Resonant converters, high-frequency systems

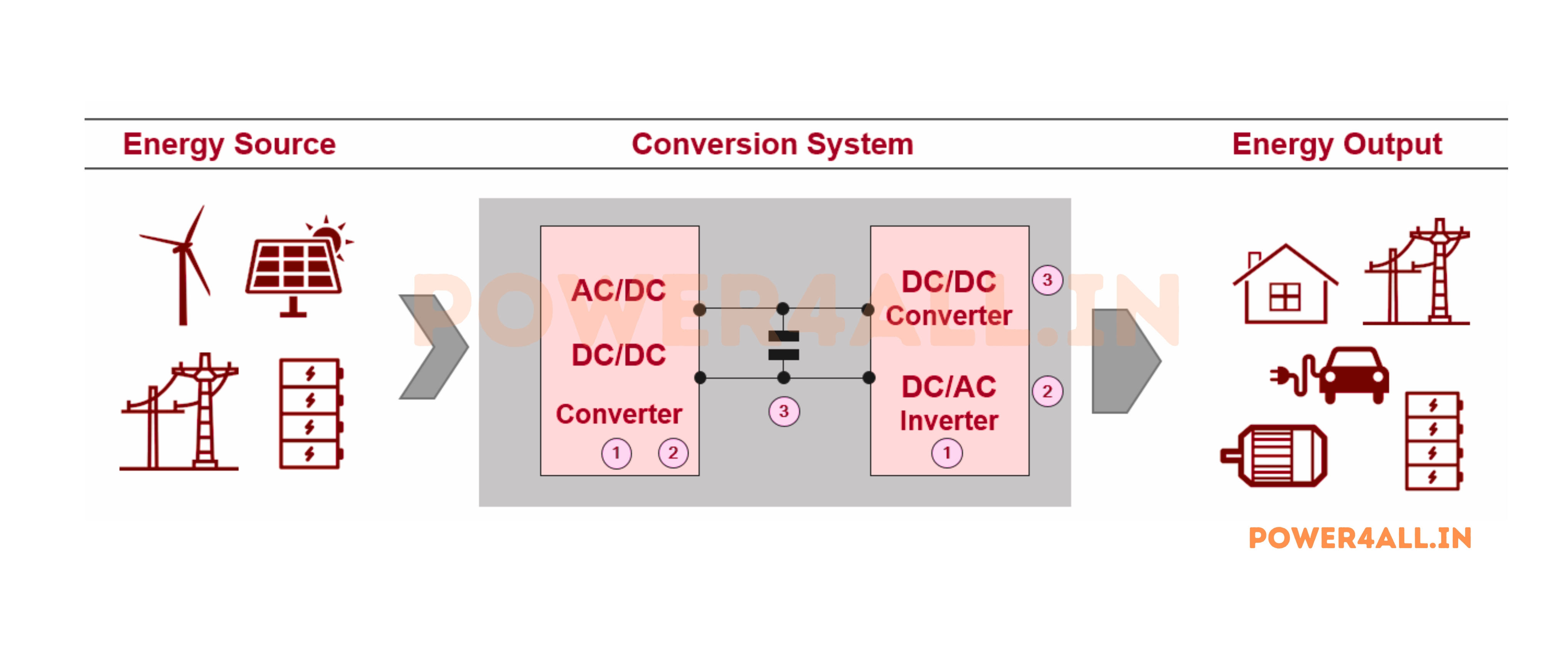

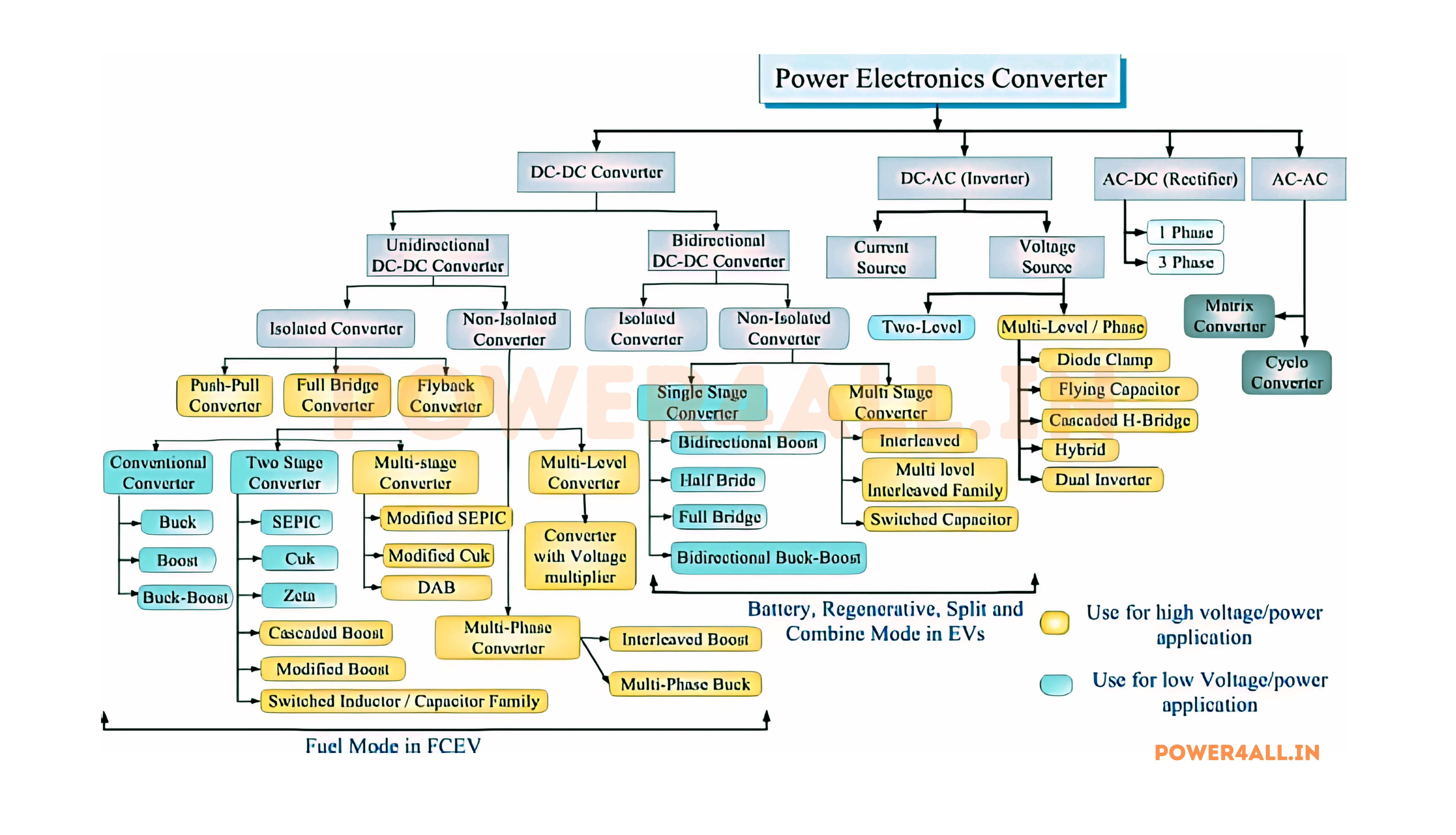

Four Main Power Conversion Types

AC to DC (Rectification)

Converting alternating current to direct current

Rectifier Classifications

- Uncontrolled (Diode): Fixed output voltage, simple, low cost, 80-85% efficiency

- Controlled (SCR/Thyristor): Variable output, phase control, 85-90% efficiency

- Active (MOSFET/IGBT): Power factor correction, low harmonics, 95-98% efficiency

- Synchronous: Active rectification with MOSFETs, highest efficiency

Critical Applications

- Power supplies for electronics (laptops, servers, LED drivers)

- DC motor drives in industrial applications (mills, cranes)

- Battery chargers (EVs, phones, tools, energy storage)

- Electroplating and welding equipment (precise current control)

- HVDC transmission systems (grid interconnection)

- Data center power systems (high efficiency requirements)

PF = P_real / P_apparent

Power factor is critical for grid compatibility

DC to AC (Inversion)

Converting direct current to alternating current

Inverter Classifications

- Voltage Source (VSI): PWM control, most common, 93-97% efficiency

- Current Source (CSI): Specialized industrial applications, robust

- Multilevel: High power, low harmonics, >99% efficiency

- Grid-tied: Synchronization with utility grid, smart features

Essential Applications

- Solar/wind inverters (residential to utility-scale systems)

- UPS systems (backup power, power quality improvement)

- AC motor drives (variable speed, energy efficient)

- Grid-tie systems (feeding power back to utility grid)

- Electric vehicle powertrains (traction motor control)

- Audio amplifiers (Class D, high efficiency)

THD = √(∑H²₂₋∞) / H₁

Total Harmonic Distortion measures output quality

DC to DC (Chopper)

Converting DC voltage to different DC voltage level

Topology Classifications

- Buck (Step-down): V_out < V_in, 90-98% efficiency

- Boost (Step-up): V_out > V_in, 85-95% efficiency

- Buck-Boost: V_out can be higher or lower, polarity inversion

- Isolated: Galvanic isolation using transformers, safety

Ubiquitous Applications

- Laptop adapters (19V to 5V, 3.3V, 1.8V rails)

- Automotive systems (12V/24V to various voltages)

- LED drivers (constant current control for lighting)

- Solar MPPT controllers (maximum power tracking)

- Phone chargers (fast charging protocols)

- Server power supplies (48V to multiple voltages)

V_out = D × V_in

Buck converter voltage relationship (D = duty cycle)

AC to AC (Cycloconverter)

Converting AC to different frequency/voltage AC

Conversion Methods

- Cycloconverters: Direct frequency conversion, 0-1/3 input frequency

- Matrix converters: Any input to any output frequency

- AC voltage controllers: Same frequency, variable voltage

Specialized Applications

- Variable frequency drives (motor speed control)

- Induction heating (high frequency for heating)

- Light dimmers (phase control for lighting)

- Soft starters (reduced voltage starting)

Key Feature: Direct conversion without intermediate DC stage

Critical Performance Parameters

| Parameter | Definition & Formula | Typical Values | Why It Matters | Improvement Methods |

|---|---|---|---|---|

| Efficiency (η) | η = (P_out/P_in) × 100% | 85-99% | Reduces energy costs, heat generation | Better devices, optimized switching |

| Power Factor (PF) | PF = P_real/P_apparent | 0.8-1.0 | Utility system efficiency, billing | Active PFC circuits, harmonic filters |

| THD (Total Harmonic Distortion) | THD = √(∑harmonics²)/fundamental | < 5% (excellent) | Power quality, EMI compliance | Advanced modulation, filtering |

| Ripple Factor | r = V_ac_rms/V_dc | < 1% | Output smoothness, load performance | Better filtering, higher frequency |

| Load Regulation | LR = (V_no_load - V_full_load)/V_rated | ± 1-5% | Voltage stability under varying load | Feedback control, better design |

| Line Regulation | LR = ΔV_out/ΔV_in × 100% | < 0.5% | Immunity to input voltage variations | Better control loops, regulation |

Power Quality Considerations

Harmonics Management

Power electronic switches create harmonics that can interfere with other equipment. Modern designs use advanced PWM techniques and filters to minimize harmonic content.

Dynamic Response

Fast switching enables rapid response to load changes, maintaining stable output even with sudden load variations - crucial for sensitive electronic equipment.

Thermal Management

Even with high efficiency, thermal design is critical. Modern systems use advanced heat sinks, thermal pads, and intelligent thermal monitoring.

Protection Systems

Built-in protection against overvoltage, overcurrent, overtemperature, and short circuits ensures safe operation and prevents catastrophic failures.

Power Semiconductor Devices

Power semiconductor devices are the heart of power electronics, acting as controllable switches that can handle high voltages and currents while switching at high speeds. Understanding their characteristics, limitations, and proper selection is crucial for designing efficient and reliable power electronic systems.

Device Categories by Control Capability

Uncontrolled Devices (Diodes)

Automatic one-way current flow based on voltage polarity

Power Diode Types & Applications

- Standard Recovery (>1μs): Line frequency applications, cost-effective

- Fast Recovery (50-200ns): High-frequency switching, reduced losses

- Schottky Diodes: Low forward drop (0.3V), very fast, low power

- SiC Diodes: High temperature (200°C), ultra-fast, efficient

Critical Applications

- Rectifier circuits: Converting AC to DC in power supplies

- Freewheeling diodes: Protecting against inductive kickback

- Voltage clamping: Protection against overvoltage spikes

- Reverse polarity protection: Preventing damage from wrong connections

Semi-Controlled (Thyristors)

Can be turned ON with gate signal, turn OFF naturally at zero current

Thyristor Family Members

- SCR (Silicon Controlled Rectifier): Basic thyristor, unidirectional

- TRIAC: Bidirectional thyristor, AC control applications

- GTO (Gate Turn-Off): Can be turned off with negative gate current

- MCT (MOS Controlled Thyristor): MOSFET gate drive capability

High-Power Applications

- Phase-controlled rectifiers: Variable DC output voltage

- AC voltage controllers: Light dimmers, motor soft starters

- HVDC transmission: High-voltage DC power transmission

- Static VAR compensators: Power factor correction

Fully Controlled Devices

Complete ON/OFF control with gate/base signals

Modern Power Switches

- Power MOSFET: Voltage controlled, very fast switching, low/medium power

- IGBT: Combines MOSFET + BJT benefits, medium/high power

- Power BJT: Current controlled, older technology, still used

- Wide Bandgap (SiC/GaN): Next-generation, ultra-efficient

Modern Applications

- Switch-mode power supplies: Efficient DC-DC conversion

- PWM inverters: Clean AC generation from DC

- Motor drives: Variable speed and torque control

- Renewable energy: Solar/wind power conversion

Comprehensive Device Comparison & Selection Guide

| Device Type | Voltage Rating | Current Rating | Switching Speed | Control Method | Efficiency | Best Applications |

|---|---|---|---|---|---|---|

| Power MOSFET | 20V - 1000V | 1A - 200A | Very Fast (10-100ns) | Voltage controlled | 95-98% | DC-DC converters, low voltage high frequency |

| IGBT | 600V - 6500V | 10A - 3000A | Fast (0.1-2μs) | Voltage controlled | 94-97% | Motor drives, inverters, medium frequency |

| SCR/Thyristor | 400V - 10kV | 1A - 5000A | Slow (10-100μs) | Current triggered | 98-99% | High power, line frequency, HVDC |

| SiC MOSFET | 650V - 3300V | 5A - 500A | Ultra-fast (5-50ns) | Voltage controlled | 98-99.5% | EV chargers, high efficiency, high temp |

| GaN FET | 30V - 650V | 1A - 100A | Ultra-fast (1-10ns) | Voltage controlled | 98-99% | Very high frequency, compact designs |

Wide Bandgap Semiconductor Revolution

Silicon Carbide (SiC)

Revolutionary material properties for ultra-efficient power conversion

| Parameter | Silicon | SiC | Improvement |

|---|---|---|---|

| Bandgap (eV) | 1.12 | 3.26 | 3× wider bandgap |

| Breakdown Field (MV/cm) | 0.3 | 3.0 | 10× higher |

| Thermal Conductivity (W/cm·K) | 1.5 | 4.9 | 3× better heat dissipation |

| Operating Temperature (°C) | 150 | 200+ | 50°C+ higher operation |

SiC Revolutionary Applications

- Electric vehicles: 50% smaller, 30% more efficient powertrains

- Solar inverters: 99%+ efficiency, reduced cooling requirements

- Data centers: Higher power density, lower cooling costs

- Industrial drives: Higher switching frequency, better performance

Gallium Nitride (GaN)

Ultra-high frequency operation in compact packages

Unique Advantages

- Ultra-fast switching: MHz operation capability

- Low switching losses: Minimal energy waste during transitions

- Small form factor: Enables extremely compact designs

- High power density: More power in smaller packages

- Low gate charge: Easy to drive, fast switching

| Application | Traditional Si | GaN Solution | Benefits |

|---|---|---|---|

| Phone Chargers | 65W in 200g package | 100W in 150g package | 50% more power, 25% lighter |

| Laptop Adapters | 90W brick-sized | 100W palm-sized | 70% size reduction |

| Server PSUs | 2.5kW, 94% efficiency | 3kW, 96% efficiency | Higher power, better efficiency |

Power Converters Overview

Power converters are complete systems that transform electrical energy from one form to another with high efficiency and precise control. They combine power semiconductor devices, passive components, and intelligent control circuits.

Converter System Architecture

Power Stage

Contains power semiconductors, magnetic components, and capacitors. Handles the actual power conversion with minimal losses.

Control System

Microcontroller or DSP-based control with real-time feedback, protection algorithms, and communication interfaces.

Protection Circuits

Overcurrent, overvoltage, overtemperature, and fault detection with fast shutdown capabilities.

Monitoring & Interface

Status indicators, parameter adjustment, communication protocols for system integration.

Rectifiers: AC to DC Conversion

Rectifiers convert alternating current (AC) to direct current (DC) and form the foundation of most electronic systems.

Uncontrolled Rectifiers

Half-Wave Rectifier

V_dc = V_m / π ≈ 0.318 V_m

Average output voltage

- Efficiency: 40.6%

- Ripple factor: 1.21

- Use: Educational purposes only

Full-Wave Bridge

V_dc = 2V_m / π ≈ 0.636 V_m

Better utilization

- Efficiency: 81.2%

- Ripple factor: 0.48

- Use: Most common type

Controlled Rectifiers

Phase-Controlled Rectification

By controlling the firing angle (α) of thyristors, we can vary the output voltage.

V_dc = (2V_m / π) × cos(α)

Output voltage control through firing angle

Applications

- DC motor drives

- Battery chargers

- Electroplating systems

- Variable DC power supplies

Inverters: DC to AC Conversion

Inverters convert direct current (DC) to alternating current (AC) and are critical components in renewable energy systems, motor drives, and UPS systems.

Inverter Types by Waveform

Square Wave Inverters

V_rms = V_dc

Simple relationship

- THD: 48.3%

- Efficiency: 90-95%

- Cost: Lowest

- Use: Simple applications

Pure Sine Wave (PWM)

V_rms = M × V_dc / √2

Where M is modulation index

- THD: <3%

- Efficiency: 93-97%

- Cost: Highest

- Use: Critical applications

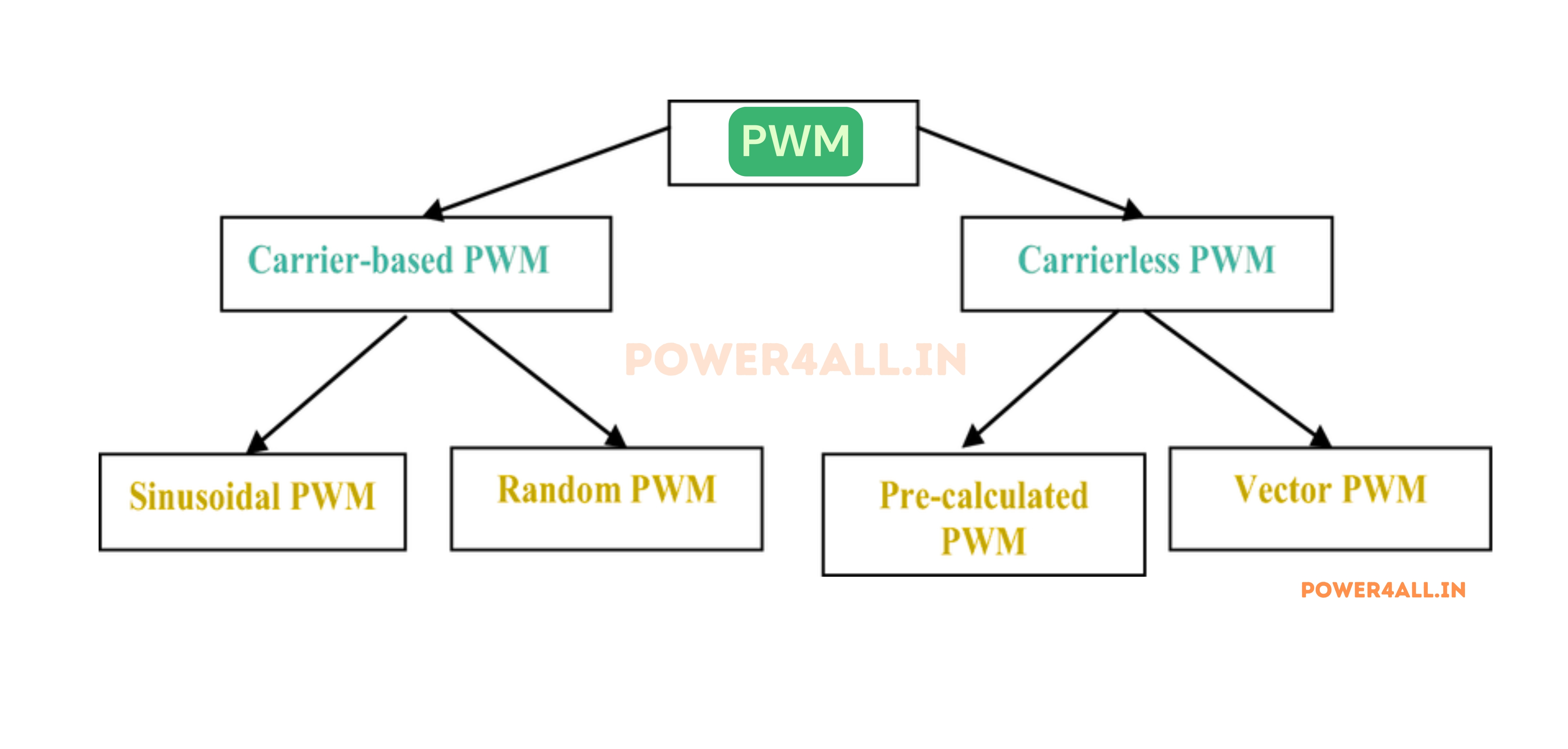

PWM Control Techniques

| PWM Technique | THD Performance | Applications | Complexity |

|---|---|---|---|

| Sinusoidal PWM | 5-15% | Basic motor drives, UPS | Low |

| Space Vector PWM | 3-8% | High-performance drives | Medium |

| Selective Harmonic Elimination | 2-5% | High-power inverters | High |

DC-DC Converters (Choppers)

DC-DC converters convert DC input voltage to a different DC output voltage level with high efficiency.

Basic Topologies

Buck Converter (Step-Down)

V_out = D × V_in

Where D is duty cycle

- Voltage gain: 0 < V_out/V_in < 1

- Efficiency: 85-95%

- Use: Laptop adapters, CPU voltage regulators

Applications

- Laptop power supplies

- CPU voltage regulation

- LED drivers

- Automotive electronics

Boost Converter (Step-Up)

V_out = V_in / (1 - D)

Theoretical relationship

- Voltage gain: V_out/V_in > 1

- Efficiency: 80-95%

- Use: Solar MPPT, LED drivers

Applications

- Solar MPPT controllers

- Battery backup systems

- LED backlighting

- Power factor correction

Buck-Boost & Advanced

V_out = -V_in × D / (1 - D)

Output polarity inverted

- SEPIC: Non-inverting, continuous input current

- Ćuk: Continuous input/output current

- ZETA: High current, low ripple

Specialized Uses

- Battery-powered systems

- Automotive applications

- Multi-output supplies

- High-current CPU power

Isolated DC-DC Converters

| Topology | Power Range | Key Features | Applications |

|---|---|---|---|

| Flyback | 1W - 150W | Simple, low cost | Phone chargers, small PSU |

| Forward | 50W - 500W | Continuous output current | Computer power supplies |

| Full-Bridge | 500W - 10kW+ | High power capability | Industrial power supplies |

| LLC Resonant | 100W - 5kW | Soft switching, high efficiency | Server PSU, EV chargers |

AC-AC Cycloconverters

AC-AC converters directly convert alternating current from one voltage and/or frequency to another without an intermediate DC stage.

AC Voltage Controllers

Phase Control Method

AC voltage controllers use phase angle control to vary the RMS output voltage.

V_rms = V_m × √[(π - α + sin(2α)/2) / π]

For resistive loads with firing angle α

Applications

- Light dimmers

- Motor soft starters

- Heating control

- Voltage regulation

Variable Frequency Drives

Indirect AC-AC Conversion

AC → DC → AC with variable frequency

- Rectifier stage: AC to DC

- DC link: Energy storage

- Inverter stage: DC to variable AC

- Control system: V/f or vector control

Applications

- Motor speed control

- Pump drives

- Fan control

- Conveyor systems

Matrix Converters

Direct AC-AC conversion

- Bidirectional power flow

- Compact design

- Sinusoidal input/output

- Unity power factor

V_out_max = 0.866 × V_in

Maximum voltage transfer ratio

Applications

- Aerospace systems

- High-speed drives

- Marine propulsion

- Wind turbines

Control Techniques & PWM

Control techniques determine how switches operate to achieve desired output characteristics.

PWM Fundamentals

Basic PWM Principle

PWM controls the average power delivered by rapidly switching between ON and OFF states.

D = t_on / T

Duty cycle (D)

| Parameter | Range | Effect |

|---|---|---|

| Switching Frequency | 1kHz - 1MHz | Smaller filters, higher losses |

| Duty Cycle | 0 - 100% | Controls average output |

| Dead Time | 50ns - 2μs | Prevents shoot-through |

Advanced PWM Techniques

Sinusoidal PWM

- Linear modulation

- Low harmonic distortion

- Simple implementation

- 78.5% DC bus utilization

Space Vector PWM

- 15% better DC utilization

- Lower harmonic distortion

- Optimized switching

- Digital implementation

Practical Applications

Power electronics revolutionized modern technology, from efficient lighting to electric vehicles and renewable energy systems.

Consumer Electronics

Mobile Device Charging

- USB PD: Up to 240W intelligent negotiation

- GaN chargers: 100W in palm-sized packages

- Wireless charging: Qi standard up to 50W

- Efficiency: >90% with modern designs

Technical Features

- Universal 100-240V AC input

- Multiple output voltages (5V-28V)

- Advanced protection systems

- Temperature monitoring

LED Lighting

- Efficiency: 130-200 lumens/watt

- Lifespan: 50,000+ hours

- Energy savings: 80-90% vs incandescent

- Control: Dimming, color tuning

Driver Technologies

- Constant current control

- Power factor correction

- Smart lighting protocols

- Flicker-free operation

Electric Vehicle Revolution

| EV Component | Power Rating | Efficiency | Technology | Key Features |

|---|---|---|---|---|

| Traction Inverter | 50-400kW | >98% | SiC MOSFETs | Variable speed motor control |

| Onboard Charger | 3-22kW | >95% | PFC + LLC resonant | AC grid to battery charging |

| DC-DC Converter | 2-5kW | >95% | LLC resonant | High voltage to 12V conversion |

| Fast Charger | 150-350kW | >96% | Modular SiC design | Rapid DC charging |

Renewable Energy Systems

Solar Power

- String inverters: 1-100kW residential/commercial

- Microinverters: Panel-level optimization

- Power optimizers: Module-level MPPT

- Central inverters: MW-scale utility systems

Performance Metrics

- Peak efficiency >99%

- MPPT efficiency >99.9%

- Grid compliance standards

- Anti-islanding protection

Wind Power

- Power range: 2-15MW per turbine

- Converter efficiency: >97%

- Grid support: Voltage/frequency regulation

- Fault tolerance: Grid disturbance capability

Advanced Features

- Variable speed operation

- Power factor control

- Low voltage ride-through

- Reactive power support

Energy Storage

- Residential: 5-20kWh systems

- Commercial: Peak demand reduction

- Utility-scale: 100MWh+ grid storage

- Microgrids: Islanding capability

Smart Features

- Bidirectional power flow

- Grid services provision

- Battery management integration

- Predictive analytics

Industrial Applications

| Industry | Applications | Power Range | Energy Savings | Key Benefits |

|---|---|---|---|---|

| Manufacturing | Variable speed drives, robotics | 1kW - 10MW | 20-50% | Precise speed/torque control |

| HVAC Systems | Variable air volume, heat pumps | 5kW - 1MW | 30-60% | Load-adaptive operation |

| Water Treatment | Pump drives, aeration systems | 10kW - 5MW | 25-45% | Flow and pressure control |

| Mining | Conveyor systems, grinding mills | 100kW - 50MW | 15-30% | Torque control, soft starting |

Safety Considerations

Safety is paramount in power electronics due to high voltages, currents, and stored energy.

Electrical Safety

| Voltage Level | Classification | Required Precautions | Applications |

|---|---|---|---|

| < 50V | Generally Safe | Basic insulation | Electronics, low voltage |

| 50-1000V AC | Low Voltage | Qualified personnel, PPE | Industrial equipment |

| 1-35kV | Medium Voltage | Specialized training | Distribution systems |

| > 35kV | High Voltage | Expert personnel | Transmission systems |

Protection Systems

Overcurrent Protection

Fuses, circuit breakers, and electronic protection with microsecond response times.

Thermal Protection

Temperature monitoring, thermal modeling, and cooling systems prevent overheating.

Ground Fault Protection

GFCI devices, insulation monitoring, and arc fault detection.

Emergency Procedures

Safe shutdown procedures, emergency contacts, and proper training.

Troubleshooting Guide

Effective troubleshooting requires systematic approaches and proper tools.

DIMES Methodology

Common Failure Modes

| Component | Common Failure | Typical Cause | Prevention |

|---|---|---|---|

| Power Devices | Gate oxide breakdown | Overvoltage, ESD | Proper gate protection |

| Capacitors | ESR increase | Aging, temperature | Derating, quality parts |

| Magnetics | Core saturation | Overcurrent | Proper design margins |

| Control | Logic errors | EMI, noise | Good layout, filtering |

Advanced Topics

The future of power electronics lies in advanced technologies including AI integration and wireless power transfer.

Emerging Technologies

AI-Powered Control

Machine learning algorithms for optimal performance and predictive maintenance.

Wireless Power Transfer

Contactless energy transfer for convenience and safety applications.

Quantum Technologies

Quantum computing for optimization and quantum materials for zero-loss transmission.

IoT Integration

Connected power systems with digital twins and blockchain for secure energy trading.

Frequently Asked Questions

Common questions about power electronics answered by experts.

What's the difference between power electronics and regular electronics?

Power electronics focuses on converting and controlling electrical power (watts to megawatts), while regular electronics processes information signals (milliwatts to watts).

| Aspect | Regular Electronics | Power Electronics |

|---|---|---|

| Function | Information processing | Energy conversion |

| Power | mW to W | W to MW |

| Focus | Speed, accuracy | Efficiency, reliability |

Why is efficiency so important in power electronics?

- Energy savings: 1% improvement in 1MW system saves $1000+ annually

- Heat reduction: Less cooling required, smaller systems possible

- Battery life: Longer operation in portable devices

- Environmental impact: Reduced power generation requirements

What skills are needed for a career in power electronics?

Technical Foundation

Circuit analysis, electromagnetic theory, control systems, semiconductor physics

Practical Skills

PCB design, simulation tools, oscilloscope operation, thermal analysis

Programming

C/C++ for embedded systems, Python for analysis, FPGA programming

Soft Skills

Project management, teamwork, communication, problem-solving

Conclusion & Future of Power Electronics

Power electronics has evolved from simple rectification circuits to sophisticated systems enabling our modern digital world. As we face global challenges in energy efficiency and climate change, power electronics will play an increasingly critical role.

Key Takeaways

Fundamental Understanding

Power electronics is about efficient energy conversion using switching techniques. The core principle minimizes power loss to achieve 95-99% efficiency.

Universal Applications

From smartphone chargers to electric vehicles to renewable energy systems, power electronics is ubiquitous in modern life.

Continuous Innovation

Wide bandgap semiconductors, AI control, and quantum technologies promise even higher efficiency and new capabilities.

Safety & Reliability

Proper design, protection systems, and adherence to standards ensure safe operation while maximizing performance.

Future Developments

| Technology | Impact | Applications |

|---|---|---|

| SiC/GaN mainstream adoption | 50%+ efficiency improvement | EV charging, renewables |

| AI-optimized control | Self-optimizing systems | Smart grids, autonomous systems |

| Quantum technologies | Zero-loss transmission | Space-based power, fusion |

Join the Revolution

Whether you're a student, engineer, or entrepreneur, you can contribute to the power electronics future. The technology offers unlimited opportunities for innovation and meaningful contribution to a sustainable future.

Future = Innovation × Efficiency × Sustainability

The power electronics equation for a better tomorrow

The future of energy is in your hands. The journey starts now.