Complete Transformer Mastery Guide

Master the fundamentals of transformers - from basic principles and electromagnetic induction to advanced applications in power systems and electronics

Complete Learning Path - Transformer Fundamentals to Applications

Navigate through comprehensive coverage of transformers from basic principles to advanced applications

What is a Transformer?

A transformer is an electrical device that transfers electrical energy between two or more circuits through electromagnetic induction. Think of it as an electrical "gear system" that can increase (step up) or decrease (step down) voltage levels while maintaining power conservation, making it one of the most fundamental components in electrical power systems.

Vp/Vs = Np/Ns = Is/Ip

Primary to Secondary Voltage, Turns, and Current Ratio

Why Transformers are Essential

Transformers are the backbone of our electrical infrastructure. Without them, efficient power transmission over long distances would be impossible, and most electronic devices couldn't operate safely from wall outlets.

Voltage Transformation

Step voltage up for efficient long-distance transmission or step down for safe use in homes and devices.

Electrical Isolation

Provide galvanic isolation between circuits, enhancing safety and preventing ground loops.

Impedance Matching

Match impedances between different circuit sections for maximum power transfer efficiency.

Power Conservation

Transfer power with minimal losses while changing voltage and current levels according to circuit needs.

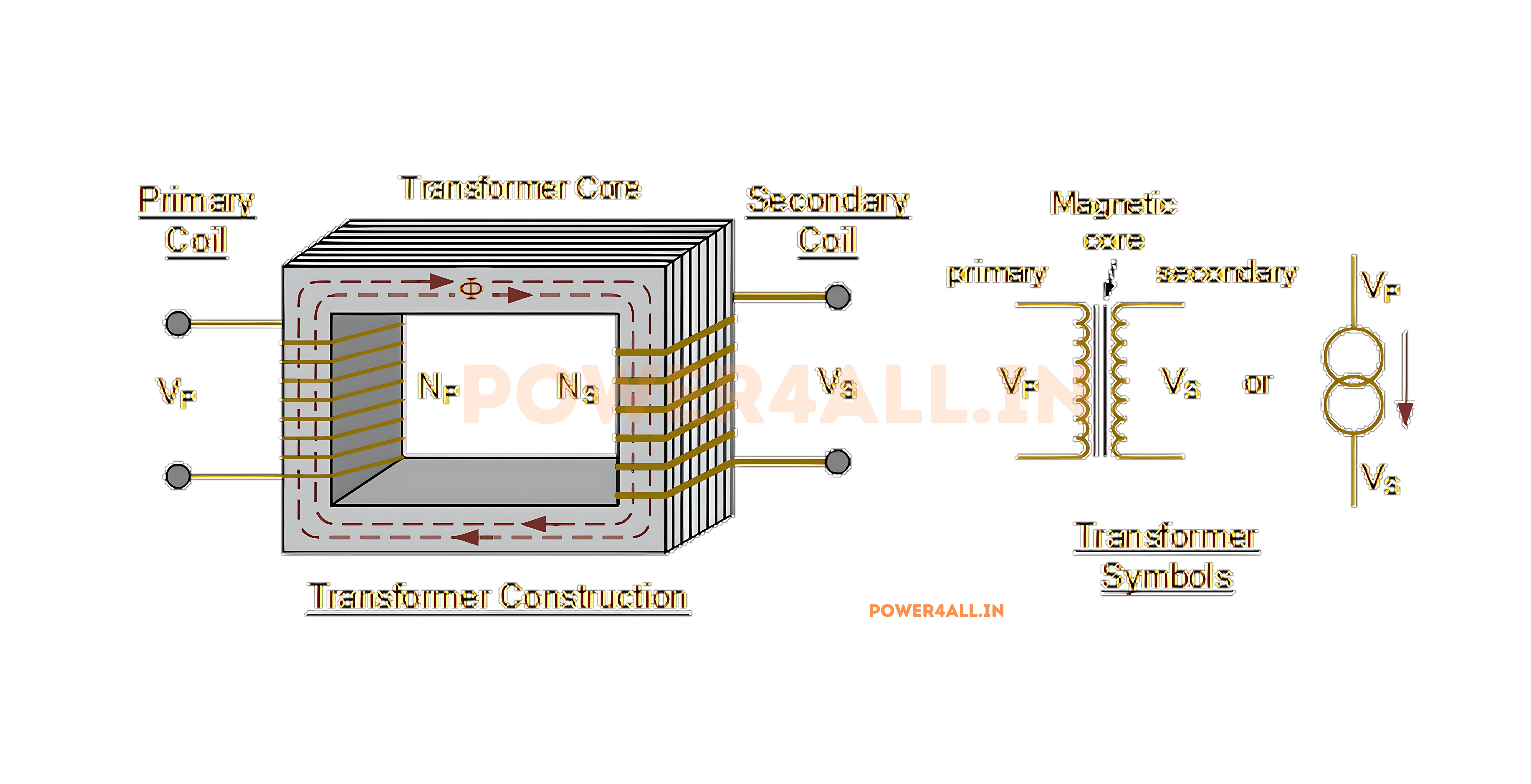

Transformer Symbol and Basic Principles

Circuit Symbols

- Iron Core: Two coils with parallel lines (core symbol)

- Air Core: Two coils without core lines

- Variable: Arrow through symbol

- Auto-transformer: Single coil with tap

- Current transformer: Special CT symbol

Key Parameters

- Turns Ratio (a): Np/Ns - determines voltage transformation

- Power Rating: Maximum power it can handle safely

- Frequency: Operating frequency (50Hz/60Hz for power)

- Efficiency: Percentage of input power delivered to output

- Regulation: Voltage change from no-load to full-load

Everyday Transformer Examples

- Phone charger: Step-down transformer converting 120V AC to 5V DC

- Microwave: Step-up transformer providing high voltage for magnetron

- Distribution transformer: 4160V to 240V/120V for neighborhood supply

- Current transformer: Measuring high currents safely in power meters

- Audio transformer: Matching microphone impedance to amplifier input

- Isolation transformer: Providing safety isolation in medical equipment

Did You Know?

The first transformer was invented in 1886 by William Stanley Jr. Modern power transformers can be 99.7% efficient and handle hundreds of megawatts of power. The largest power transformers weigh over 400 tons and cost millions of dollars!

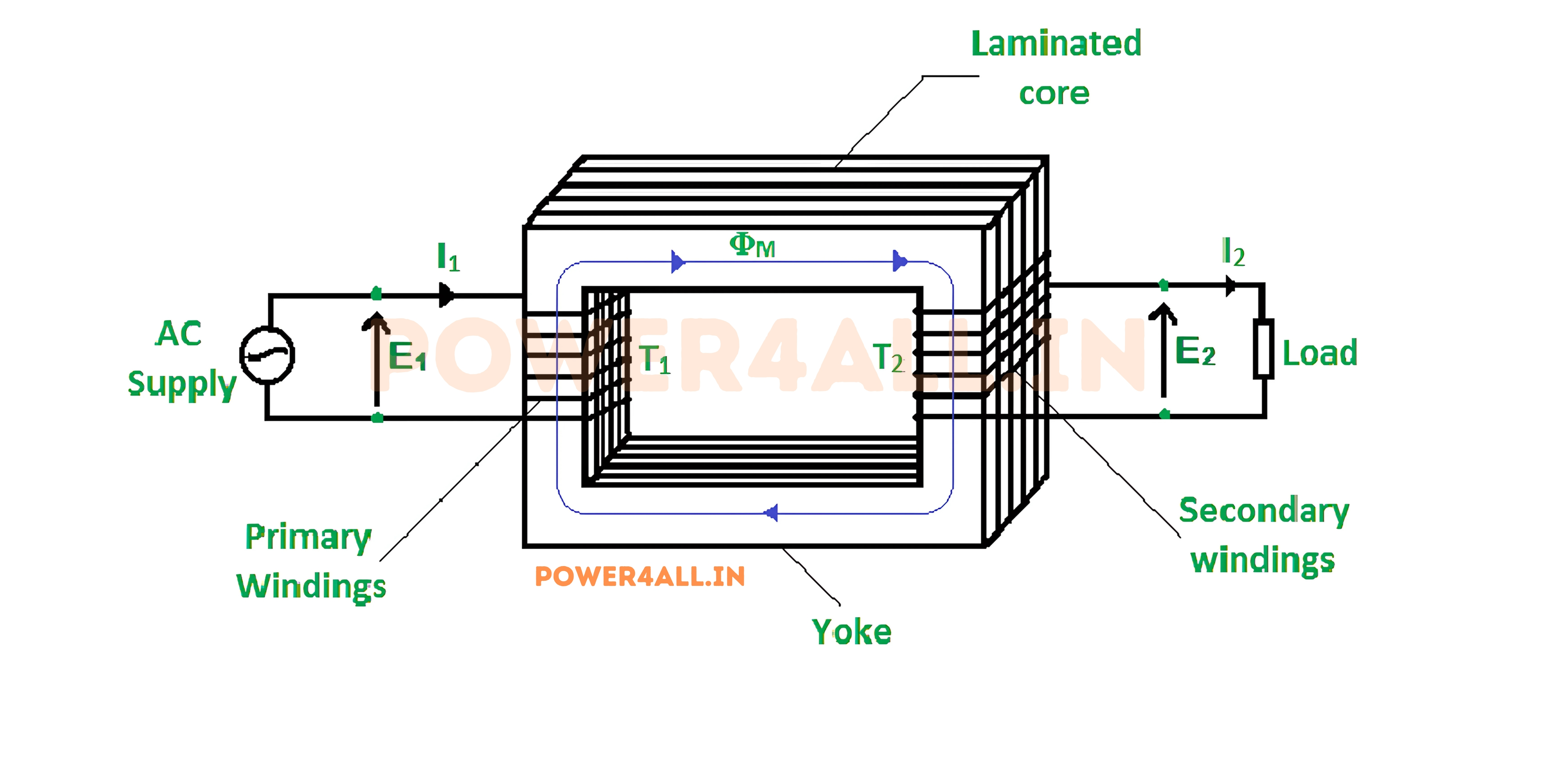

Transformer Fundamentals: How They Work

Understanding transformer operation requires grasping the principles of electromagnetic induction, mutual inductance, and magnetic circuits. These concepts explain how transformers can transfer electrical energy between circuits without any physical connection.

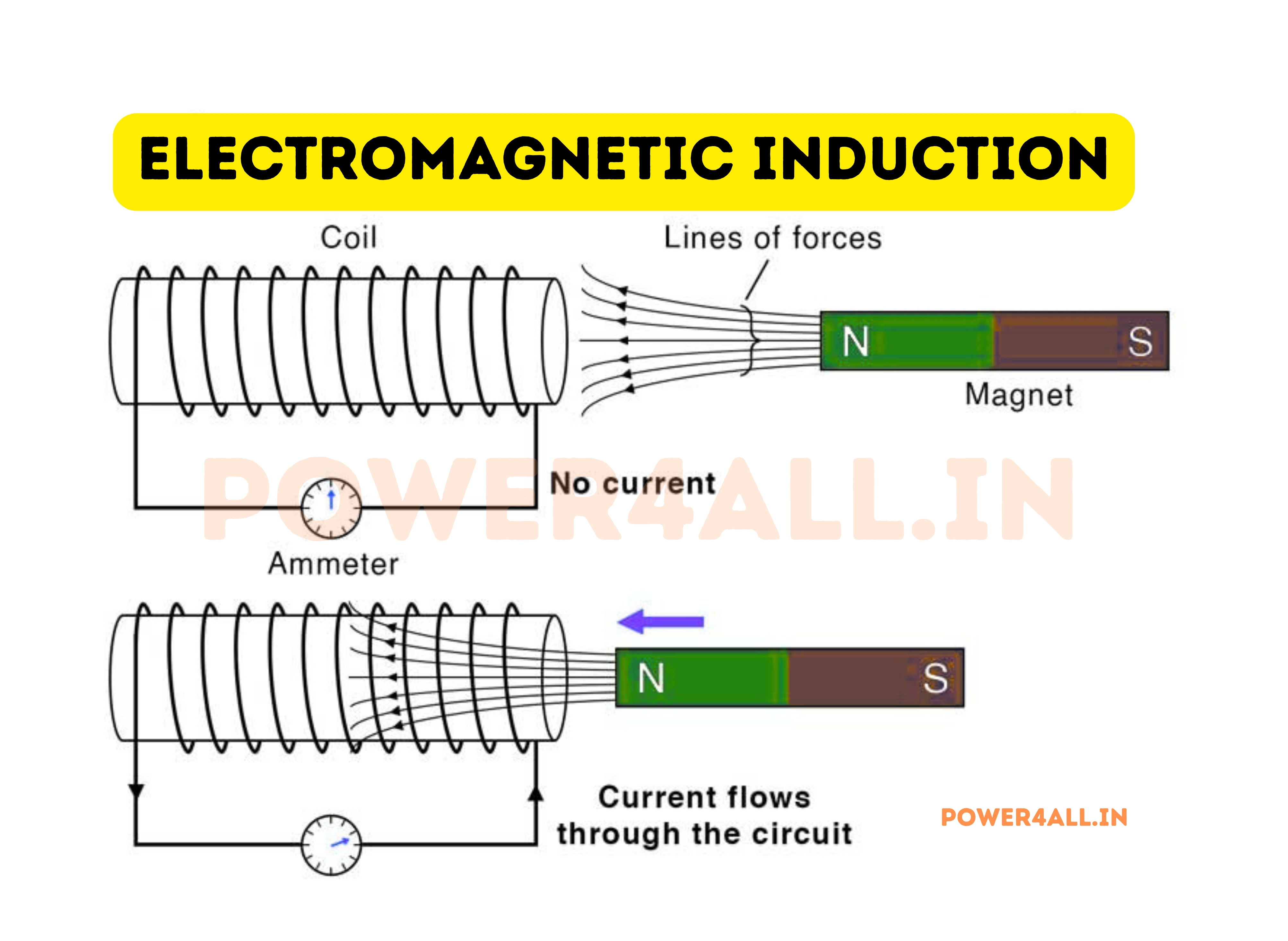

Faraday's Law of Electromagnetic Induction

The Physical Principle Behind Transformer Operation

Transformers work because of Faraday's fundamental discovery: a changing magnetic field induces an electric field (and therefore voltage) in nearby conductors. This is the physical principle that enables energy transfer without direct electrical connection.

The Step-by-Step Process

ε = -N × dΦ/dt

Induced EMF = Number of turns × Rate of flux change

Key Factors Affecting Induction

| Factor | Effect on Induced Voltage | Why This Happens | Practical Implication |

|---|---|---|---|

| Number of Turns | More turns = Higher voltage | Each turn adds to total induced EMF | Voltage ratio equals turns ratio |

| Rate of Flux Change | Faster change = Higher voltage | Derivative relationship in Faraday's law | Higher frequency increases voltage |

| Core Material | Better core = Higher efficiency | High permeability concentrates flux | Iron cores much better than air |

| Core Geometry | Closed path = Better coupling | Minimizes flux leakage | Toroidal cores most efficient |

Mutual Inductance and Coupling

What is Mutual Inductance?

Mutual inductance (M) quantifies how effectively magnetic flux from one coil links with another coil. Perfect coupling means all flux from primary links with secondary, while poor coupling means much flux is lost.

M = k√(L₁L₂)

M = mutual inductance, k = coupling coefficient

Coupling Coefficient Values

- k = 1.0: Perfect coupling (theoretical)

- k = 0.95-0.99: Excellent (iron core transformers)

- k = 0.8-0.95: Good (ferrite core transformers)

- k = 0.1-0.8: Fair (air core, loose coupling)

- k < 0.1: Poor coupling (significant losses)

Ideal vs Real Transformer Behavior

Understanding Practical Limitations and Losses

Ideal Transformer Assumptions

Perfect Conditions

- 100% coupling: All flux links both windings

- Zero resistance: No I²R losses in windings

- Infinite permeability: Core requires no magnetizing current

- No flux leakage: Perfect magnetic circuit

- No core losses: No hysteresis or eddy current losses

Real-World Effects

- Winding resistance: I²R losses cause heating and voltage drop

- Leakage inductance: Flux that doesn't link both windings

- Magnetizing current: Current needed to establish core flux

- Core losses: Hysteresis and eddy current losses

- Saturation: Core magnetic saturation at high flux levels

Transformer Equivalent Circuit

Components of Real Transformer Model

- R₁, R₂: Primary and secondary winding resistances

- X₁, X₂: Primary and secondary leakage reactances

- Xₘ: Magnetizing reactance (infinite in ideal case)

- Rᶜ: Core loss resistance (infinite in ideal case)

- a: Ideal transformer with turns ratio

| Parameter | Ideal Value | Typical Real Value | Effect on Performance |

|---|---|---|---|

| Efficiency | 100% | 95-99.7% | Power losses as heat |

| Voltage regulation | 0% | 1-5% | Output voltage varies with load |

| No-load current | 0 | 2-10% of rated | Magnetizing and core loss current |

| Frequency response | Perfect | Limited bandwidth | Leakage inductance limits high frequency |

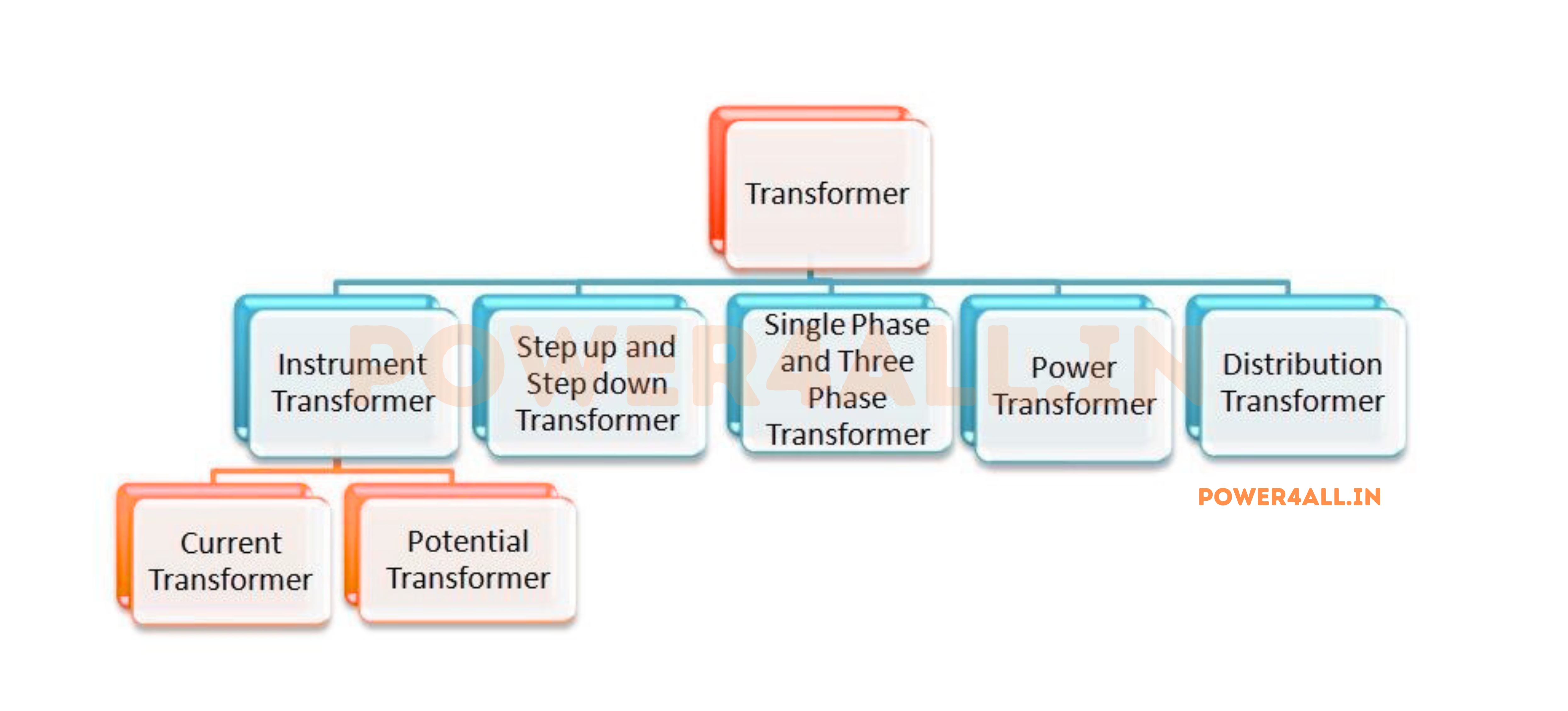

Types of Transformers: Complete Classification

Transformers come in many varieties, each designed for specific applications and operating conditions. Understanding the different types helps in selecting the right transformer for power transmission, electronics, measurement, or specialized applications.

Power Transformers

Distribution Transformers

Step down high voltage for consumer use

Typical Voltage Levels

- Primary: 4.16kV, 12.47kV, 25kV, 35kV

- Secondary: 120V, 240V, 480V

- Power ratings: 10kVA to 5000kVA

- Installation: Pole-mounted or pad-mounted

- Cooling: Oil-filled or dry-type

Key Features

- High efficiency (98-99%)

- Designed for continuous operation

- Multiple secondary taps

- Protective devices integrated

- Weather-resistant enclosures

Common Applications

- Residential neighborhood power supply

- Commercial building distribution

- Industrial plant power distribution

- Street lighting systems

- Agricultural power supply

Power Station Transformers

Step up generator voltage for transmission

Massive Scale Operations

- Generator side: 11kV, 22kV, 25kV

- Transmission side: 138kV, 230kV, 500kV, 765kV

- Power ratings: 100MVA to 1000MVA+

- Weight: 100 to 400+ tons

- Cooling: Forced oil and air circulation

Advanced Features

- On-load tap changers

- Dissolved gas analysis monitoring

- Temperature monitoring systems

- Buchholz relay protection

- Surge arresters

Critical Applications

- Nuclear power plant step-up

- Coal-fired power station transformers

- Hydroelectric generator step-up

- Wind farm collection transformers

- Solar farm inverter transformers

Isolation Transformers

Safety isolation without voltage change

Safety and Protection

- Turns ratio: 1:1 (no voltage change)

- Primary purpose: Galvanic isolation

- Insulation: High voltage breakdown rating

- Grounding: Isolated secondary ground system

- Noise reduction: Eliminates common-mode noise

Critical Safety Applications

- Medical equipment power supply

- Computer and server power

- Test equipment isolation

- Audio system ground loop elimination

- Sensitive instrumentation power

Measurement and Control Transformers

Instrument Transformers for Measurement and Protection

Current Transformers (CTs)

Current transformers step down high currents to safe, measurable levels (typically 5A or 1A secondary) while maintaining proportional relationship to primary current.

Metering CTs

- Accuracy class: 0.1, 0.2, 0.5 for revenue metering

- Burden: Low impedance for accurate measurement

- Saturation: Designed to avoid saturation at rated current

- Applications: kWh meters, power quality monitoring

- Safety: Secondary must never be open-circuited

Protection CTs

- Accuracy class: 5P, 10P for protective relaying

- High fault current: Must operate accurately during faults

- Saturation characteristics: Designed for fault current levels

- Applications: Overcurrent relays, differential protection

- Multiple cores: Separate cores for metering and protection

Voltage Transformers (VTs/PTs)

| Type | Primary Voltage | Secondary Voltage | Accuracy Class | Application |

|---|---|---|---|---|

| Low voltage VT | 120V - 600V | 120V | 0.3, 0.6 | Panel meters, protection |

| Medium voltage VT | 2.4kV - 35kV | 120V | 0.3, 0.6, 1.2 | Switchgear metering |

| High voltage VT | 46kV - 800kV | 120V | 0.3, 0.6 | Transmission protection |

| Capacitive VT (CVT) | 115kV - 800kV | 120V | 0.3, 0.6 | EHV transmission systems |

Special Purpose Transformers

Audio Transformers

Optimized for audio frequency range

Audio-Specific Features

- Frequency response: 20Hz to 20kHz flat response

- Low distortion: Minimal harmonic distortion

- Impedance matching: Match microphones to amplifiers

- Isolation: Break ground loops in audio systems

- Shielding: Magnetic shielding from interference

Audio Applications

- Microphone input transformers

- Audio line isolation transformers

- Speaker matching transformers

- Tube amplifier output transformers

- Professional audio balancing

High-Frequency Transformers

Switching power supply and RF applications

High-Frequency Design

- Ferrite cores: Low losses at high frequencies

- Litz wire: Reduces skin effect losses

- Minimal turns: Reduces leakage inductance

- Tight coupling: Maximizes efficiency

- Thermal management: High power density challenges

Modern Applications

- Switch-mode power supplies

- DC-DC converters

- Flyback transformers

- RF impedance matching

- Wireless power transfer

Auto-transformers

Single winding with multiple taps

Auto-transformer Advantages

- Higher efficiency: Only part of power is transformed

- Smaller size: Less copper and iron required

- Lower cost: Economical for small voltage changes

- Better regulation: Lower impedance

- Continuous adjustment: Variable ratio possible

Safety Note

Auto-transformers provide no electrical isolation between primary and secondary. Use only where isolation is not required.

Transformer Construction & Materials

The performance, efficiency, and reliability of a transformer depend heavily on its construction materials and design. Understanding core materials, winding techniques, and insulation systems is crucial for selecting and applying transformers effectively.

Core Materials and Design

Silicon Steel Laminations

Standard material for power transformers

Material Properties

- Composition: Iron with 3-4% silicon content

- Grain orientation: Oriented or non-oriented steel

- Thickness: 0.23mm to 0.35mm laminations

- Insulation: Oxide coating between laminations

- Permeability: High magnetic permeability

Advantages

- Low core losses (hysteresis and eddy current)

- High saturation flux density

- Excellent mechanical properties

- Cost-effective for large transformers

- Proven reliability over decades

Core Construction Types

- E-I laminations: Easy to wind, moderate efficiency

- E-E laminations: Better magnetic circuit, less leakage

- C-cores: Reduced air gaps, higher efficiency

- Toroidal: Maximum efficiency, minimal stray field

Ferrite Cores

High-frequency and switch-mode applications

Ferrite Characteristics

- Material: Ceramic magnetic material (iron oxides)

- Frequency range: 1kHz to several MHz

- Core shapes: E, EE, ETD, RM, toroidal

- Saturation: Lower than silicon steel but adequate

- Temperature stability: Good up to 100-200°C

Applications

- Switch-mode power supply transformers

- DC-DC converter transformers

- High-frequency inductors

- EMI suppression components

- Wireless power transfer coils

| Ferrite Grade | Frequency Range | Permeability | Application |

|---|---|---|---|

| 3C90 | 25kHz - 200kHz | 2300 | Power transformers |

| 3C94 | 50kHz - 500kHz | 2800 | SMPS transformers |

| 3F3 | 100kHz - 1MHz | 2000 | High-frequency transformers |

Air Core and Other Materials

Specialized applications and materials

Air Core Transformers

- No magnetic core: Windings on non-magnetic former

- Linear operation: No saturation effects

- High frequency: No core losses at RF frequencies

- Low coupling: Typically 0.1 to 0.8 coupling coefficient

- Applications: RF transformers, Tesla coils

Advanced Core Materials

- Amorphous steel: Very low core losses

- Nanocrystalline: Ultra-low losses, high frequency

- Powder cores: Distributed air gap, high current

- Supermalloy: Extremely high permeability

Winding Design and Conductor Materials

Conductor Selection and Winding Techniques

Conductor Materials

| Material | Conductivity | Advantages | Applications |

|---|---|---|---|

| Copper | 100% (standard) | Excellent conductivity, ductile, solders well | Most transformer windings |

| Aluminum | 61% | Lightweight, lower cost, good for large transformers | Large power transformers |

| Silver | 106% | Best conductivity, oxidation resistant | High-end audio, RF applications |

| Litz wire | Variable | Reduces skin effect at high frequency | High-frequency transformers |

Winding Configurations

Concentric Windings

Primary and secondary windings placed concentrically around the core. Good coupling, easy to manufacture, most common configuration.

Interleaved Windings

Primary and secondary sections alternated along the core. Better coupling, reduced leakage inductance, more complex construction.

Pancake Windings

Flat, disc-shaped coils stacked and interconnected. Excellent for high-voltage applications, good cooling, precise control.

Helical Windings

Continuous helical winding with crossover connections. Used in high-current applications, good mechanical strength.

Insulation Systems

Electrical Insulation and Thermal Management

Insulation Classes and Temperature Ratings

| Class | Temperature Limit | Typical Materials | Applications |

|---|---|---|---|

| Class A | 105°C | Paper, cotton, natural resins | Small power transformers |

| Class E | 120°C | Synthetic resins, enamel films | General purpose transformers |

| Class B | 130°C | Mica, fiberglass, polyester | Medium power transformers |

| Class F | 155°C | High-grade synthetic materials | Modern power transformers |

| Class H | 180°C | Silicone resins, polyimide | High-temperature applications |

Insulation System Components

Primary Insulation

- Wire enamel: Thin coating on magnet wire

- Tape wrapping: Additional layer on wire

- Slot liners: Insulation in core slots

- Turn-to-turn: Between adjacent wire turns

- Layer-to-layer: Between winding layers

Major Insulation

- Primary-to-secondary: Between windings

- Winding-to-core: Ground insulation

- Bushing insulation: Terminal connections

- Oil barriers: In oil-filled transformers

- Surge protection: Lightning and switching surges

Transformer Equations & Calculations

Understanding transformer mathematics is essential for proper design, selection, and application. The fundamental relationships between voltage, current, turns, and power govern all transformer operations and enable precise calculations for any application.

Basic Transformer Equations

Vp/Vs = Np/Ns = a

Voltage Transformation Ratio

Ip/Is = Ns/Np = 1/a

Current Transformation Ratio

Pp = Ps (ideal)

Power Conservation Principle

Basic Calculation Example

Transformer: 120V:24V, 100VA

- Turns ratio: a = 120/24 = 5:1

- Primary current: Ip = 100VA/120V = 0.83A

- Secondary current: Is = 100VA/24V = 4.17A

- Current ratio: Ip/Is = 0.83/4.17 = 1/5 ✓

- Check: Np/Ns = 5, Is/Ip = 5 ✓

Impedance Transformation

Impedance Reflection

How secondary impedance appears to primary

Z'p = a² × Zs

Secondary impedance referred to primary

Impedance Matching Example

Match 8Ω speaker to 600Ω amplifier output:

- Required ratio²: 600/8 = 75

- Turns ratio: a = √75 = 8.66:1

- Primary sees: 8.66² × 8Ω = 600Ω ✓

- Maximum power transfer achieved

Load Analysis

Calculating primary current from secondary load

Load Calculation

2:1 step-down, 10Ω secondary load, 120V primary:

- Secondary voltage: 120V/2 = 60V

- Secondary current: 60V/10Ω = 6A

- Primary current: 6A/2 = 3A

- Primary impedance: 2² × 10Ω = 40Ω

- Check: 120V/40Ω = 3A ✓

Regulation and Efficiency Calculations

Performance Calculations for Real Transformers

Voltage Regulation

Voltage regulation measures how much the secondary voltage changes from no-load to full-load conditions. Good regulation means stable output voltage.

%Regulation = [(Vnl - Vfl)/Vfl] × 100%

Where Vnl = no-load voltage, Vfl = full-load voltage

| Transformer Type | Typical Regulation | Causes of Voltage Drop | Improvement Methods |

|---|---|---|---|

| Small power transformers | 3-8% | Winding resistance, leakage reactance | Larger wire, better coupling |

| Distribution transformers | 1-3% | Internal impedance, load power factor | Tap changers, impedance optimization |

| Large power transformers | 0.5-2% | Precise impedance control | On-load tap changers |

Efficiency Calculations

η = Pout/(Pout + Losses) × 100%

Efficiency = Output Power / (Output + Losses)

Types of Losses

Copper Losses (I²R)

Resistive losses in windings. Proportional to current squared. Varies with load.

Core Losses

Hysteresis and eddy current losses in core material. Constant regardless of load.

Stray Losses

Losses due to leakage flux in structural parts. Usually small but frequency dependent.

Short Circuit and Fault Calculations

Fault Current and Protection Calculations

Short Circuit Current

When the secondary is short-circuited, the impedance of the transformer limits the fault current. This is crucial for protective device coordination.

Isc = Vp/Zp

Short circuit current limited by transformer impedance

Fault Current Calculation

100kVA, 4160V:480V transformer, 5% impedance:

- Base current (secondary): 100,000VA/480V = 208A

- Fault current: 208A/0.05 = 4,160A

- Primary side fault: 100,000VA/4160V/0.05 = 481A

- Protection required: Circuit breakers rated for fault current

Transformer Impedance

| Transformer Size | Typical Impedance | Fault Current Factor | Application Notes |

|---|---|---|---|

| Small power (1-100kVA) | 2-6% | 17-50 × normal | Higher impedance for current limiting |

| Distribution (100-2500kVA) | 3-7% | 14-33 × normal | Balance between regulation and fault current |

| Power (>2500kVA) | 6-15% | 7-17 × normal | Higher impedance for system stability |

Power Ratings & Efficiency

Transformer power ratings and efficiency are critical specifications that determine the operating capabilities, thermal performance, and economic viability of transformer applications. Understanding these parameters ensures safe operation and optimal performance.

Power Rating Fundamentals

Understanding VA Rating

Transformers are rated in VA (Volt-Amperes) rather than Watts because the actual power depends on the load power factor. The VA rating represents the maximum apparent power the transformer can handle safely.

S = V × I

Apparent Power (VA) = Voltage × Current

Power Factor Considerations

- Resistive load (PF=1.0): VA = Watts

- Inductive load (PF=0.8): VA = Watts ÷ 0.8

- Capacitive load (PF=0.8): VA = Watts ÷ 0.8

- Mixed load: Complex calculation required

Power Rating Example

1000VA transformer supplying different loads:

- Resistive heater (PF=1.0): 1000W

- Inductive motor (PF=0.8): 800W

- LED driver (PF=0.6): 600W

- Mixed industrial load (PF=0.85): 850W

Note: Same transformer, different usable power based on load characteristics.

Standard Power Ratings

| Application Category | Typical VA Range | Voltage Classes | Common Applications | Efficiency Range |

|---|---|---|---|---|

| Electronic/Control | 1VA - 1kVA | 5V - 600V | Power supplies, controls, instrumentation | 85-95% |

| Small Power | 1kVA - 100kVA | 120V - 4160V | Machine tools, HVAC, lighting | 95-97% |

| Distribution | 100kVA - 5MVA | 4kV - 35kV | Commercial buildings, industrial plants | 97-99% |

| Power Station | 5MVA - 1000MVA | 11kV - 765kV | Power generation, transmission | 99-99.7% |

Efficiency Analysis

Detailed Efficiency Calculations and Optimization

All-Day Efficiency

For transformers that operate at varying loads throughout the day, all-day efficiency provides a better measure of overall performance than full-load efficiency.

ηall-day = ∑(Power × Time) / ∑[(Power + Losses) × Time]

Energy-weighted efficiency over operating cycle

All-Day Efficiency Calculation

Distribution transformer daily load cycle:

- Light load (25%): 16 hours, 98.5% efficiency

- Medium load (50%): 6 hours, 98.8% efficiency

- Heavy load (100%): 2 hours, 98.2% efficiency

All-day efficiency calculation:

- Energy delivered: (0.25×16 + 0.50×6 + 1.0×2) = 9 units

- Energy consumed: (4.06/98.5 + 3.04/98.8 + 2.04/98.2) = 9.17 units

- All-day efficiency: 9/9.17 = 98.1%

Loss Distribution

Core Losses (No-Load)

- Hysteresis losses: Energy lost in magnetization cycles

- Eddy current losses: Circulating currents in core

- Constant with load: Present whenever energized

- Frequency dependent: Increase with frequency

- Typical values: 0.1-1% of rated power

Copper Losses (Load)

- I²R losses: Resistive heating in windings

- Variable with load: Proportional to current squared

- Temperature dependent: Increase with temperature

- Skin effect: Higher at higher frequencies

- Typical values: 0.5-3% at full load

Efficiency Optimization Techniques

Core Design

Use high-grade silicon steel, optimize flux density, minimize core joints and air gaps.

Winding Design

Use larger conductors, minimize winding length, optimize current density for thermal limits.

Thermal Management

Improve cooling system, use better insulation materials, optimize operating temperature.

Load Management

Optimal load matching, avoid overloading, implement proper voltage regulation systems.

Transformer Connections & Configurations

Transformer connections and configurations determine how transformers integrate into power systems and affect voltage relationships, current flow, and system performance. Understanding these configurations is essential for power system design and three-phase applications.

Single-Phase Transformer Connections

Center-Tap Configuration

Split secondary winding for dual voltage output

Configuration Details

- Secondary split: Two equal voltage outputs

- Center point: Usually grounded for reference

- Voltage relationship: Each half = total voltage ÷ 2

- Current capability: Each output handles half total current

- Common voltages: 24V center-tap (12-0-12V)

Center-Tap Applications

- Full-wave rectifier circuits

- Push-pull amplifier power supplies

- Dual-polarity power supplies (±12V)

- Audio amplifier output transformers

- Battery charger circuits

Multiple Secondary Windings

Several independent secondary outputs

Design Advantages

- Isolation: Complete electrical isolation between outputs

- Different voltages: Multiple voltage levels from one transformer

- Load independence: Loading one secondary doesn't directly affect others

- Ground isolation: Each secondary can have its own ground reference

- Safety: Low voltage outputs isolated from high voltage primary

Multi-Secondary Example

Power supply transformer with multiple outputs:

- Primary: 120V AC input

- Secondary 1: 24V, 2A for control circuits

- Secondary 2: 12V, 5A for logic circuits

- Secondary 3: 5V, 10A for digital systems

- Total VA: 48 + 60 + 50 = 158VA minimum

Auto-Transformer Connections

Single winding with tap connections

Auto-Transformer Characteristics

- Shared winding: Common winding for primary and secondary

- No isolation: Primary and secondary electrically connected

- Higher efficiency: Only portion of power is transformed

- Smaller size: Less copper and iron required

- Lower cost: Economical for voltage adjustments

Safety Warning

Auto-transformers provide no electrical isolation. Use only where isolation is not required. Not suitable for medical or safety-critical applications.

Three-Phase Transformer Connections

Delta, Wye, and Zigzag Configurations

Delta (Δ) Connection

Delta Connection Properties

- Configuration: Three windings connected in triangle

- Line voltage: Equals winding voltage

- Line current: √3 times winding current

- No neutral point: Three-wire system only

- Harmonic circulation: Third harmonics circulate in delta

VL = Vphase, IL = √3 × Iphase

Delta connection voltage and current relationships

Wye (Y) Connection Properties

- Configuration: Three windings connected to common neutral

- Line voltage: √3 times winding voltage

- Line current: Equals winding current

- Neutral available: Four-wire system possible

- Unbalanced loads: Better handling of unbalanced conditions

VL = √3 × Vphase, IL = Iphase

Wye connection voltage and current relationships

Common Three-Phase Configurations

| Configuration | Primary | Secondary | Phase Shift | Applications |

|---|---|---|---|---|

| Delta-Delta | Δ | Δ | 0° | Industrial motors, balanced loads |

| Wye-Wye | Y | Y | 0° | Transmission systems, balanced loads |

| Delta-Wye | Δ | Y | +30° | Step-down distribution, lighting |

| Wye-Delta | Y | Δ | -30° | Step-up generation, motors |

| Zigzag | Various | Z | Variable | Grounding, harmonic mitigation |

Phase Shift Importance

Why phase shift matters in three-phase systems:

- Parallel operation: Transformers must have same phase shift

- System stability: Phase shifts affect power flow

- Protection coordination: Relay settings depend on phase relationships

- Motor starting: Phase sequence critical for rotation direction

Practical Applications: Transformers in Real Systems

Transformers are essential components in virtually every electrical power system, from the smallest electronic devices to massive utility networks. Understanding their practical applications demonstrates the critical role transformers play in modern technology and infrastructure.

Power System Applications

Electric Power Grid

Backbone of electrical power transmission and distribution

Generation Step-Up

- Generator voltage: 11kV to 25kV typical

- Transmission voltage: 138kV to 765kV

- Efficiency benefit: Higher voltage = lower transmission losses

- Power ratings: 100MVA to 1500MVA transformers

- Critical infrastructure: Enable long-distance power transmission

Distribution Step-Down

- Substation transformers: 138kV to 12.47kV

- Distribution transformers: 12.47kV to 240V/120V

- Neighborhood supply: Serve residential and commercial loads

- Safety isolation: Protect end users from high voltages

Power Grid Voltage Levels

- Generation: 22kV → Step-up → 345kV transmission

- Transmission: 345kV → Step-down → 69kV subtransmission

- Distribution: 69kV → Step-down → 12.47kV distribution

- Utilization: 12.47kV → Step-down → 240V/120V service

Consumer Electronics

Power supplies and adapters for electronic devices

Wall Adapters and Chargers

- Input: 120V AC wall outlet

- Transformer function: Step down to safe low voltage

- Isolation safety: Protect users from line voltage

- Multiple outputs: Different voltages for various devices

- Switching vs linear: Modern designs use high-frequency transformers

Common Device Transformers

- Phone charger: 120V AC → 5V DC, 1-3A

- Laptop adapter: 120V AC → 19V DC, 3-5A

- LED driver: 120V AC → 12V DC for LED strips

- Doorbell transformer: 120V AC → 16V AC

- Audio equipment: Various voltages for different circuits

Industrial Applications

Motor drives, welding, and process control

Motor Control Systems

- Voltage matching: Match motor voltage to supply voltage

- Starting transformers: Reduce voltage for soft starting

- Isolation transformers: Protect sensitive motor controls

- Three-phase applications: Industrial motor power supplies

Welding and Heating

- Arc welding: High current, low voltage transformers

- Induction heating: High-frequency transformers

- Resistance welding: Very high current capability

- Current control: Variable tap transformers for current adjustment

Specialized Applications

Unique and Advanced Transformer Applications

Renewable Energy Systems

| Application | Transformer Type | Voltage Levels | Special Requirements |

|---|---|---|---|

| Solar inverters | High-frequency isolation | 600V DC to 240V AC | High efficiency, compact size |

| Wind turbine | Step-up power transformer | 690V to 34.5kV | Variable frequency capability |

| Battery storage | Bidirectional converter | 400V DC to 480V AC | Charge/discharge capability |

| Grid connection | Pad-mount distribution | 34.5kV to 12.47kV | Fault protection, remote monitoring |

Transformer Selection Guide

Selecting the right transformer requires careful consideration of electrical specifications, environmental conditions, safety requirements, and cost factors. This comprehensive guide helps you choose the optimal transformer for your specific application.

Primary Selection Criteria

Essential Specifications

Start with the fundamental electrical requirements that must be met for proper operation. These are non-negotiable specifications that determine basic transformer functionality.

Selection Example

Industrial control panel power supply:

- Primary: 480V AC, 3-phase, 60Hz

- Secondary: 120V AC, single-phase

- Load: 500VA continuous

- Environment: Indoor, 40°C maximum

- Safety: Industrial grade, UL listed

- Mounting: DIN rail mountable

- Selection: 750VA industrial control transformer

Load Analysis and Sizing

| Load Type | Power Factor | Inrush Current | Sizing Factor | Selection Notes |

|---|---|---|---|---|

| Resistive heating | 1.0 | 1× steady state | 1.2× load | Straightforward sizing |

| Incandescent lighting | 1.0 | 10-15× steady state | 1.5× load | Consider inrush current |

| Fluorescent lighting | 0.9 | 1.5× steady state | 1.25× load | Include ballast losses |

| LED lighting | 0.95 | 2× steady state | 1.2× load | Consider driver efficiency |

| Single-phase motors | 0.8 | 5-8× steady state | 2.0× load | High starting current |

| Electronic equipment | 0.7-0.9 | 2-3× steady state | 1.5× load | Switching power supplies |

Performance Requirements

Regulation, Efficiency, and Special Performance Needs

Voltage Regulation Requirements

Regulation Classes

- Tight regulation (±1%): Precision equipment, medical devices

- Standard regulation (±3%): General electronics, lighting

- Loose regulation (±5%): Heating, non-critical loads

- Variable loads: Consider worst-case regulation

%Reg = [(Vnl - Vfl)/Vfl] × 100

Voltage regulation calculation

Efficiency Considerations

- Energy costs: Higher efficiency reduces operating costs

- Heat generation: Lower losses reduce cooling requirements

- Environmental impact: Efficiency regulations and green building standards

- Typical efficiency: 95-99.5% for modern transformers

Efficiency Impact Example

100kVA transformer operating 8760 hours/year:

- 97% efficient: 3kW losses × 8760h = 26,280kWh/year

- 99% efficient: 1kW losses × 8760h = 8,760kWh/year

- Savings: 17,520kWh/year (significant cost difference)

Special Performance Features

K-Factor Rating

For non-linear loads (computers, LED drivers), choose transformers with appropriate K-factor rating (K-4, K-13, K-20).

Low Noise Design

Quiet operation transformers for indoor installation, residential areas, or noise-sensitive environments.

Surge Withstand

Enhanced BIL (Basic Impulse Level) rating for areas with frequent lightning or switching surges.

Temperature Rise

Standard 55°C, 65°C, or 80°C rise depending on ambient conditions and ventilation available.

Environmental and Mechanical Factors

Installation Environment

Indoor vs outdoor, temperature, humidity, contamination

Indoor Applications

- Enclosure: NEMA 1 or IP20 typically adequate

- Cooling: Natural convection or forced air

- Noise: Consider acoustic requirements

- Space constraints: Compact designs available

- Mounting: Floor, wall, or rack mounting options

Outdoor Applications

- Weather protection: NEMA 3R or IP54 minimum

- UV resistance: Weatherproof materials and finishes

- Temperature cycling: Daily temperature variations

- Corrosion protection: Marine or industrial environments

- Security: Tamper-resistant or vandal-proof designs

Mechanical Requirements

Size, weight, mounting, and accessibility

Physical Constraints

- Available space: Height, width, depth limitations

- Weight limits: Floor loading or mounting structure capacity

- Clearances: Ventilation and maintenance access

- Transportation: Doorway and hallway access during installation

Space Planning Guidelines

- Ventilation clearance: 3 feet minimum on sides

- Maintenance access: 6 feet in front of transformer

- Fire separation: 12 feet from combustible materials

- Electrical clearances: Per NEC requirements

Standards and Certifications

Safety approvals and compliance requirements

Common Standards

- UL 1561: Dry-type general purpose transformers

- UL 5085: Low voltage transformers

- IEEE C57.12.01: General requirements for transformers

- IEC 61558: International transformer standards

- CSA C227.1: Canadian standards

Certification Importance

Proper certifications are required for electrical inspection approval and insurance compliance. Always verify required certifications before purchase.

Cost Considerations and Life Cycle Analysis

Total Cost of Ownership and Economic Factors

Initial Cost vs Operating Cost

| Cost Factor | Initial Impact | Operating Impact | Lifetime Impact | Decision Criteria |

|---|---|---|---|---|

| Purchase price | High | None | Low | Budget constraints |

| Efficiency losses | Low | High | Very high | Energy cost, usage hours |

| Installation cost | Medium | None | Low | Complexity, accessibility |

| Maintenance cost | None | Low | Medium | Design quality, environment |

| Downtime cost | None | Variable | High | Reliability, criticality |

Life Cycle Cost Example

50kVA transformer, 20-year life, $0.10/kWh electricity:

- Standard efficiency (97%): $5,000 purchase + $13,000 energy = $18,000 total

- High efficiency (99%): $7,000 purchase + $4,300 energy = $11,300 total

- Premium efficiency (99.5%): $9,000 purchase + $2,200 energy = $11,200 total

- Best choice: Premium efficiency saves $6,800 over 20 years

Testing & Troubleshooting Transformers

Proper testing and troubleshooting techniques are essential for maintaining transformer performance, ensuring safety, and preventing costly failures. Understanding both routine testing procedures and diagnostic methods helps identify problems before they become critical.

Routine Testing Procedures

Basic Electrical Tests

Fundamental tests for transformer health assessment

Turns Ratio Test

- Purpose: Verify correct voltage transformation ratio

- Method: Apply known voltage to primary, measure secondary

- Equipment: TTR (Transformer Turns Ratio) tester

- Acceptance: Within ±0.5% of nameplate ratio

- Frequency: Annual or after maintenance

Insulation Resistance Test

- Purpose: Check insulation system integrity

- Method: Apply DC voltage between windings and ground

- Equipment: Megohmmeter (500V to 5000V)

- Acceptance: Minimum 1000Ω per volt rating

- Safety: Discharge capacitive charge after test

Insulation Test Example

480V transformer insulation test:

- Test voltage: 1000V DC (megger setting)

- Minimum resistance: 480V × 1000Ω/V = 480MΩ

- Typical good reading: > 10GΩ

- Poor insulation: < 100MΩ (investigate further)

High Voltage Tests

Dielectric strength and impulse testing

Hi-Pot (High Potential) Test

- Purpose: Verify insulation can withstand overvoltage

- Method: Apply high AC or DC voltage across insulation

- Voltage level: 2× rated voltage + 1000V (1 minute)

- Safety critical: Must be performed by qualified personnel

- Failure indication: Current flow above specified limit

High Voltage Safety

Hi-pot testing involves lethal voltages. Only qualified personnel with proper safety equipment should perform these tests. Follow all safety procedures and use proper lockout/tagout.

Load and Temperature Tests

Performance verification under operating conditions

Load Test

- Purpose: Verify performance at rated load

- Method: Apply resistive load equal to nameplate rating

- Measurements: Voltage regulation, efficiency, temperature

- Duration: Until thermal equilibrium reached

- Data recording: Temperature rise vs time

Temperature Rise Limits

- Class 105°C (A): 55°C rise maximum

- Class 130°C (B): 80°C rise maximum

- Class 155°C (F): 100°C rise maximum

- Class 180°C (H): 125°C rise maximum

Advanced Diagnostic Testing

Specialized Tests for Detailed Condition Assessment

Dissolved Gas Analysis (DGA)

Oil-Filled Transformer Analysis

Detecting internal faults through gas analysis

Key Gases and Their Significance

- Hydrogen (H₂): General overheating, corona discharge

- Methane (CH₄): Low temperature overheating

- Ethane (C₂H₆): Medium temperature overheating

- Ethylene (C₂H₄): High temperature overheating

- Acetylene (C₂H₂): Arcing, very high temperature

- Carbon oxides: Cellulose decomposition

| Fault Type | Key Gas | Typical Concentration | Action Required |

|---|---|---|---|

| Normal operation | All gases low | < 100 ppm total | Continue monitoring |

| Overheating | CH₄, C₂H₆ | 100-1000 ppm | Investigate, increase monitoring |

| High temperature | C₂H₄ | > 500 ppm | Urgent investigation required |

| Arcing | C₂H₂ | > 50 ppm | Immediate action, consider removal |

Frequency Response Analysis

Detecting mechanical deformation and winding displacement

SFRA (Sweep Frequency Response Analysis)

- Principle: Measures impedance vs frequency

- Frequency range: 20Hz to 2MHz typically

- Detects: Winding deformation, turn-to-turn shorts

- Comparison: Requires baseline or phase comparison

- Sensitivity: Can detect very small mechanical changes

SFRA Interpretation

- Low frequency (20Hz-2kHz): Core and shunt capacitance

- Mid frequency (2kHz-20kHz): Main winding geometry

- High frequency (20kHz-2MHz): Series capacitance, turn details

- Pattern changes: Indicate specific fault types

Partial Discharge Testing

Partial Discharge Significance

Early warning system for insulation degradation:

- Detection method: Electrical or acoustic sensors

- Units: Measured in picocoulombs (pC)

- Threshold levels: < 10pC good, > 100pC investigate

- Trending: Increasing levels indicate deterioration

- Online monitoring: Continuous assessment possible

Common Problems and Solutions

Overheating Issues

Most common transformer problem

Symptoms

- High temperature readings

- Discolored windings or oil

- Burning smell

- Reduced insulation resistance

- Accelerated aging

Causes and Solutions

- Overloading: Reduce load or install larger transformer

- Poor ventilation: Improve airflow around transformer

- High ambient temperature: Add cooling or relocate

- Harmonic currents: Install K-factor rated transformer

- Poor connections: Tighten all connections

Insulation Failures

Serious safety and equipment risk

Progressive Failure Modes

- Moisture ingress: Reduces dielectric strength

- Thermal aging: Gradual insulation degradation

- Partial discharge: Localized breakdown creating voids

- Mechanical stress: Physical damage to insulation

- Chemical contamination: Oil degradation products

Safety Priority

Insulation failures can result in dangerous flashover, fire, or explosion. Any indication of insulation problems requires immediate professional evaluation.

Noise and Vibration

Operational issues affecting environment

Noise Sources

- Magnetostriction: Core steel expansion/contraction

- Loose components: Hardware vibration

- Loading effects: Load current magnetic forces

- Cooling systems: Fan and pump noise

Mitigation Strategies

- Vibration isolation: Rubber pads, spring mounts

- Enclosure design: Sound-dampening materials

- Low-noise transformers: Special core construction

- Location considerations: Distance from noise-sensitive areas

Maintenance Best Practices

Preventive Maintenance for Long Transformer Life

Scheduled Maintenance Tasks

| Maintenance Task | Frequency | Dry Type | Oil Filled | Critical Points |

|---|---|---|---|---|

| Visual inspection | Monthly | ✓ | ✓ | Look for overheating signs, damage |

| Connection tightness | Annual | ✓ | ✓ | Use calibrated torque wrench |

| Insulation resistance | Annual | ✓ | ✓ | Compare to baseline values |

| Oil analysis | Annual | N/A | ✓ | DGA, moisture, acidity |

| Cleaning | Annual | ✓ | ✓ | Remove dust, debris, contamination |

| Thermal imaging | Semi-annual | ✓ | ✓ | Identify hot spots early |

Record Keeping and Trending

Performance Trending

Track key parameters over time to identify gradual degradation and predict maintenance needs.

Maintenance Records

Document all tests, maintenance activities, and repairs for warranty and reliability analysis.

Scheduled Reminders

Use maintenance management systems to ensure timely completion of preventive tasks.

Alarm Thresholds

Establish clear criteria for when values indicate need for immediate attention or investigation.

Safety Considerations & Best Practices

Transformer safety is paramount due to the high voltages, large amounts of stored energy, and potential hazards associated with these devices. Understanding and implementing proper safety procedures protects personnel, equipment, and the public from serious injury or death.

Electrical Safety Fundamentals

Critical Safety Warning

Transformers can retain lethal voltages even when disconnected from power sources. Stored energy in capacitance and magnetic fields can cause serious injury or death. Only qualified personnel should work on energized equipment.

High Voltage Hazards

Understanding and mitigating electrical shock risks

Voltage Categories and Risks

- Low voltage (< 1000V): Can cause serious injury or death

- Medium voltage (1-35kV): Severe burns, cardiac arrest

- High voltage (> 35kV): Instantaneous fatality risk

- Arc flash potential: Temperatures exceeding 20,000°C

- Step and touch potentials: Ground current hazards

Personal Protective Equipment (PPE)

- Arc-rated clothing: Minimum 8 cal/cm² rating

- Insulated gloves: Voltage class appropriate

- Safety glasses: Arc-rated face protection

- Hard hat: Class E electrical rating

- Safety shoes: Electrical hazard rated

Lockout/Tagout (LOTO) Procedures

Preventing accidental energization during maintenance

Essential LOTO Steps

Multi-Source Hazard

Transformers may have multiple energy sources: primary power, secondary circuits, control power, and stored energy in magnetic fields. All sources must be isolated and verified.

Fire and Explosion Hazards

Preventing and responding to transformer fires

Fire Risk Factors

- Insulating oil: Combustible liquid in oil-filled units

- Overheating: Excessive temperature causing ignition

- Arcing faults: Internal arcs igniting insulation

- External ignition: External heat sources or sparks

- Tank rupture: Pressure buildup from internal faults

Fire Prevention and Suppression

- Fire-resistant construction: Use fire-rated enclosures

- Proper clearances: Maintain combustible material separation

- Detection systems: Smoke and gas detection

- Suppression systems: Deluge sprinklers, CO₂ systems

- Emergency procedures: Evacuation and response plans

Installation Safety Requirements

Safe Installation Practices and Code Requirements

Electrical Code Requirements

| Safety Requirement | Indoor Installation | Outdoor Installation | Purpose |

|---|---|---|---|

| Clearance from walls | 3 feet minimum | 8 feet minimum | Fire prevention, maintenance access |

| Working space in front | 6 feet minimum | 10 feet minimum | Personnel safety, equipment access |

| Ventilation opening | Required per rating | Natural ventilation | Heat dissipation, prevent overheating |

| Grounding | Equipment grounding | Equipment and fence grounding | Personnel protection, fault clearing |

| Disconnecting means | Within sight or lockable | Within sight or lockable | Safe maintenance and operation |

Environmental Safety Considerations

Oil Spill Prevention

Oil containment systems, secondary containment, and spill response procedures for oil-filled transformers.

Thermal Protection

Temperature monitoring, thermal barriers, and heat dissipation measures to prevent overheating.

Noise Control

Sound level limits, noise barriers, and acoustic treatments in noise-sensitive areas.

Public Protection

Fencing, warning signs, and physical barriers to prevent public access to high voltage equipment.

Operational Safety Procedures

Qualified Personnel Requirements

Training and certification for transformer work

Qualification Categories

- Qualified electrical worker: Trained in electrical safety, hazard recognition

- Unqualified person: Limited to non-electrical tasks only

- Authorized person: Trained and approved for specific high voltage work

- Competent person: Capable of identifying existing and predictable hazards

- Supervision required: Qualified oversight for all electrical work

Required Training

- Electrical safety awareness

- Arc flash hazard recognition

- Proper use of personal protective equipment

- Lockout/tagout procedures

- Emergency response procedures

Safe Work Practices

Procedures for working around energized equipment

General Safety Rules

- De-energize when possible: Always work on de-energized equipment when feasible

- Test before touch: Verify absence of voltage with proper test equipment

- Maintain boundaries: Respect approach and working distances

- Use proper tools: Insulated tools rated for voltage level

- Work in pairs: Never work alone on electrical equipment

| Voltage Level | Approach Boundary | Working Distance | PPE Requirements |

|---|---|---|---|

| 120V - 600V | 3 feet | 1 foot | Class 0 gloves, safety glasses |

| 601V - 15kV | 5 feet | 2 feet | Class 1 gloves, face shield, arc suit |

| 15.1kV - 36kV | 6 feet | 3 feet | Class 2 gloves, full arc protection |

| 36.1kV - 138kV | 8 feet | 4 feet | Class 3 gloves, specialized equipment |

Emergency Procedures

Response protocols for electrical emergencies

Electrical Emergency Response

Critical Safety Rule

Never touch someone being electrocuted! Turn off power first or use non-conductive object to separate victim from electrical source. CPR may be required - electrical shock can cause cardiac arrest.

Frequently Asked Questions (FAQs)

Common questions about transformers, their operation, selection, and troubleshooting. These FAQs address real-world concerns and practical issues encountered when working with transformers.

Basic Transformer Questions

Q: Can I use a 60Hz transformer on 50Hz power?

A: Generally yes, but with considerations. A 60Hz transformer on 50Hz will have:

- Higher flux density: 20% increase in core flux

- Increased core losses: Slightly higher no-load losses

- Higher magnetizing current: About 20% increase

- Usually acceptable: Most transformers can handle this

- Check nameplate: Some specify frequency range

Recommendation: Derate by 10-15% for continuous 50Hz operation.

Q: Why do transformers hum?

A: Transformer humming is caused by magnetostriction - the core steel expands and contracts with the magnetic field.

- Frequency: Hum at 120Hz (twice the line frequency)

- Normal operation: Some noise is expected

- Excessive noise indicates: Loose laminations, overload, or overvoltage

- Mitigation: Vibration isolation, acoustic enclosures

- Quiet designs: Special core materials and construction

Q: Can transformers work with DC voltage?

A: Standard transformers do NOT work with DC voltage.

- AC required: Transformers need changing magnetic flux

- DC causes saturation: Core saturates, no voltage transformation

- High current: DC causes excessive primary current

- Damage risk: Can overheat and fail

- DC-DC converters: Use switching techniques with transformers

Practical Application Questions

Q: How do I calculate the right transformer size?

A: Calculate based on load requirements with safety margin:

Example: 800W load at 0.8 PF = 1000VA, with 25% margin = 1250VA, select 1500VA transformer.

Q: Can I parallel transformers for more capacity?

A: Yes, but with strict requirements:

- Same voltage ratio: Identical turns ratios required

- Same impedance: Within 7.5% for good current sharing

- Same phase shift: Delta-delta, wye-wye, etc.

- Same frequency rating: Both designed for same frequency

- Proper phasing: Correct polarity connections

- Protection: Individual protection for each transformer

Professional installation recommended for parallel transformer installations.

Q: What causes transformer failures?

A: Common failure modes and prevention:

- Overheating (40%): Overload, poor ventilation, ambient temperature

- Insulation failure (25%): Age, moisture, contamination

- Short circuits (20%): External faults, lightning

- Mechanical damage (10%): Vibration, shipping damage

- Manufacturing defects (5%): Poor quality control

Prevention: Proper sizing, maintenance, protection, and monitoring.

Troubleshooting Questions

| Problem | Possible Causes | Diagnostic Steps | Solutions |

|---|---|---|---|

| No output voltage | Open primary, blown fuse, wiring error | Check input voltage, fuses, connections | Replace fuse, check wiring, test continuity |

| Low output voltage | Overload, high impedance, low input voltage | Measure load current, input voltage | Reduce load, check supply voltage, verify connections |

| Overheating | Overload, poor ventilation, overvoltage | Check load, measure temperature, verify voltage | Reduce load, improve cooling, install larger transformer |

| Excessive noise | Loose laminations, overvoltage, overload | Check input voltage, load current, physical condition | Tighten mounting, reduce voltage/load, vibration isolation |

| Tripping breakers | Overload, short circuit, inrush current | Measure load current, check for shorts | Reduce load, repair shorts, use slow-blow fuses |

Selection and Specification Questions

Q: Indoor vs Outdoor Transformers?

A: Outdoor transformers have weatherproof enclosures (NEMA 3R+), UV-resistant materials, and drainage. Indoor transformers are typically NEMA 1 with ventilation louvers. Cost difference is 20-40%.

Q: Temperature Rise Ratings?

A: Standard rise is 55°C, 65°C, or 80°C above 40°C ambient. Higher rise allows smaller size but shorter life. Each 10°C increase halves insulation life (8-degree rule).

Q: When to Use Isolation Transformers?

A: Required for medical equipment, test benches, computer systems where ground loop elimination or safety isolation is needed. Cost premium is 15-25% over auto-transformers.

Q: K-Factor Ratings for Non-Linear Loads?

A: K-4 for general lighting, K-13 for computers/office equipment, K-20 for heavy non-linear loads. K-factor transformers cost 10-30% more but prevent overheating with harmonic loads.

Mastering Transformers: Your Journey Forward

Transformers are fundamental to our modern electrical infrastructure, from the massive power system transformers that deliver electricity to our communities, to the tiny switching transformers in our electronic devices. Understanding these versatile components opens doors to countless applications in electrical engineering and electronics.

Key Takeaways

Fundamental Principles

Electromagnetic induction enables voltage transformation while conserving power. The simple relationship V₁/V₂ = N₁/N₂ governs transformer operation across all applications.

Practical Applications

From 1VA control transformers to 1000MVA power transformers, the same principles apply. Proper selection requires understanding load characteristics, environment, and safety requirements.

Safety First

Transformers involve potentially lethal voltages and stored energy. Professional training, proper procedures, and appropriate safety equipment are essential for safe operation.

Remember the Basics

Whether you're working with a phone charger or a substation transformer, the fundamental principles remain the same. Start with Ohm's law, understand power relationships, and always prioritize safety.

Knowledge + Safety + Practice = Success

The formula for transformer mastery

Final Checklist

- ✓ Understand electromagnetic induction principles

- ✓ Know how to calculate transformer parameters

- ✓ Recognize different transformer types and applications

- ✓ Appreciate safety requirements and procedures

- ✓ Understand selection criteria and specifications

- ✓ Know basic testing and troubleshooting methods

- ✓ Appreciate future technology trends

Congratulations!

You've completed a comprehensive journey through transformer technology. From basic electromagnetic principles to advanced applications, you now have the knowledge foundation to work confidently with transformers in your projects and career. Remember: continuous learning and respect for safety will serve you well in the exciting field of electrical engineering.

Thank you for learning with Power4all!

Continue exploring our other comprehensive guides on electronic components and circuit design.