Complete Resistor Mastery Guide

Master the fundamentals of resistors - from basic concepts and color codes to advanced applications in modern electronics and circuit design

Complete Learning Path - Resistor Fundamentals to Applications

Navigate through comprehensive coverage of resistors from basic principles to advanced applications

What is a Resistor?

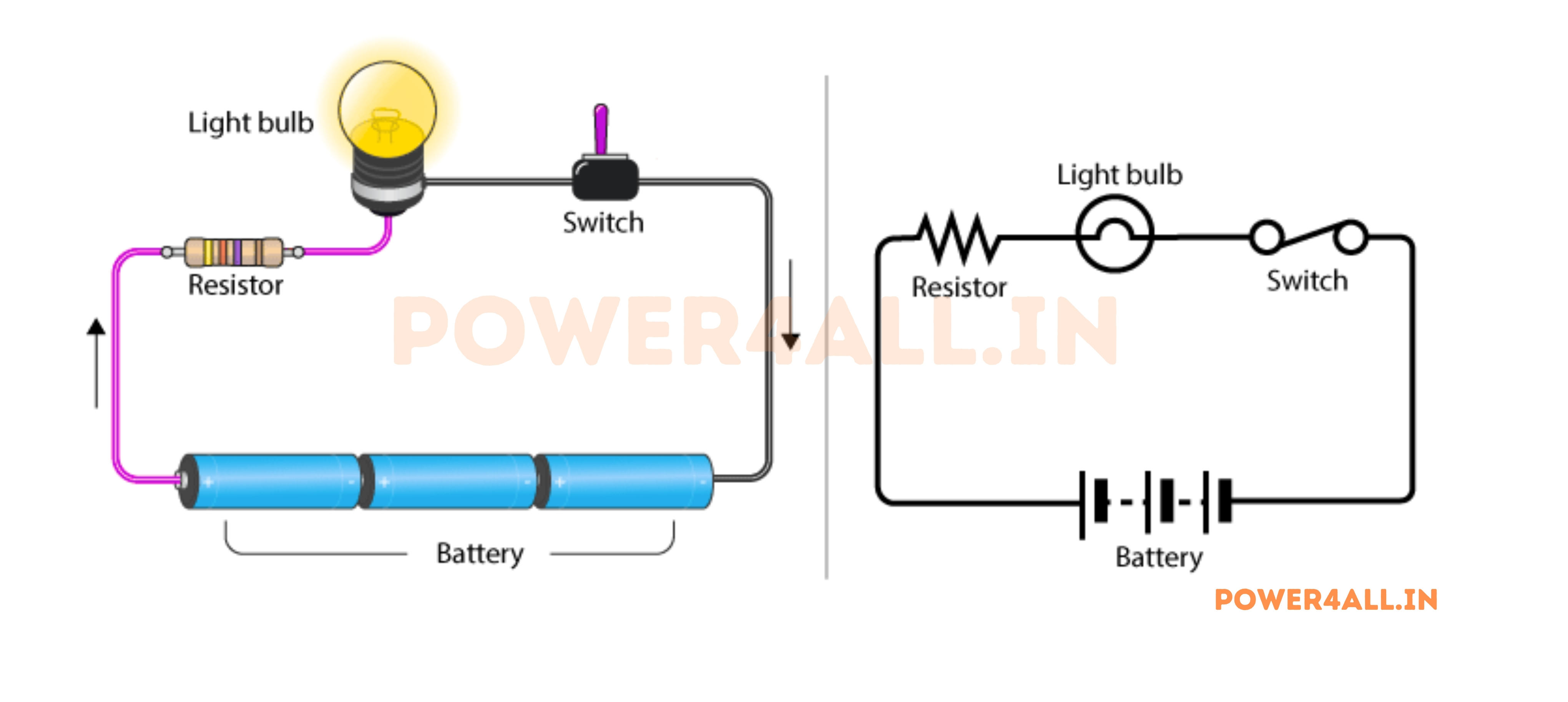

A resistor is a passive electronic component that opposes the flow of electric current, creating a voltage drop across its terminals. Think of it like a narrow section in a water pipe that restricts water flow - resistors do the same thing with electricity, and this property makes them one of the most fundamental and essential components in all electronic circuits.

The Water Pipe Analogy

Imagine water flowing through a pipe. If you place a narrow section in the pipe, it restricts the water flow and creates pressure differences. Similarly, a resistor restricts electrical current and creates voltage differences.

Perfect Comparison

- Water flow restriction → Current flow restriction

- Pipe narrowing → Resistor material property

- Pressure drop → Voltage drop across resistor

- Flow rate control → Current level control

R = V / I

Resistance equals Voltage divided by Current (Ohm's Law)

Why Resistors are Essential

Resistors might seem like simple components that just "resist" current, but they're actually the workhorses of electronics. Without resistors, most electronic circuits would be impossible to build because we need precise control over current and voltage levels.

Current Control

Resistors limit current to safe levels for sensitive components like LEDs, microprocessors, and sensors, preventing damage from overcurrent.

Voltage Division

Resistors create specific voltage levels needed by different parts of a circuit, like converting 12V to 5V for digital logic circuits.

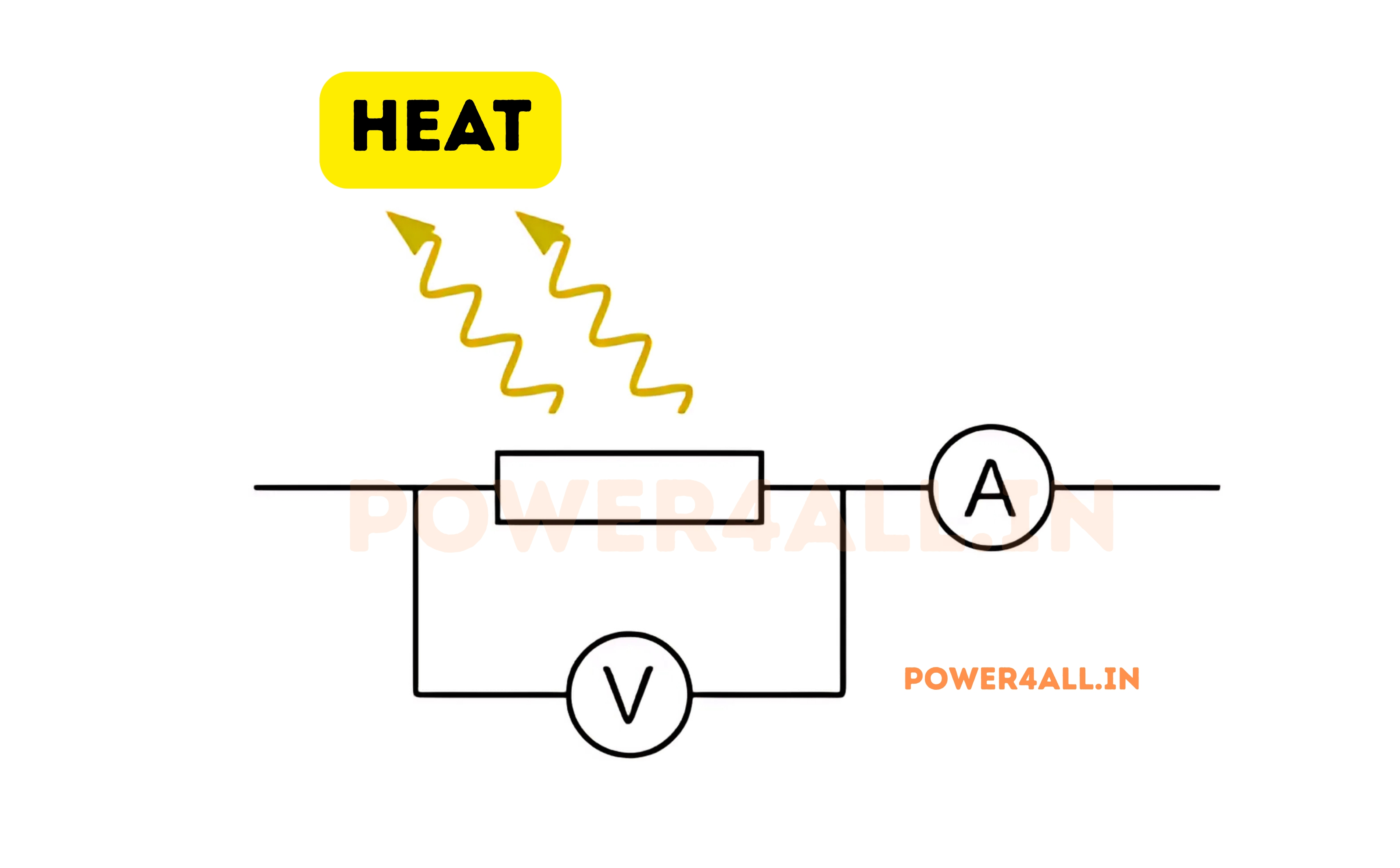

Heat Generation

Resistors convert electrical energy to heat energy, used in applications like electric heaters, toasters, and hair dryers.

Signal Conditioning

Resistors shape electrical signals, filter noise, and set operating points for amplifiers and other active components.

Resistor Symbol and Units

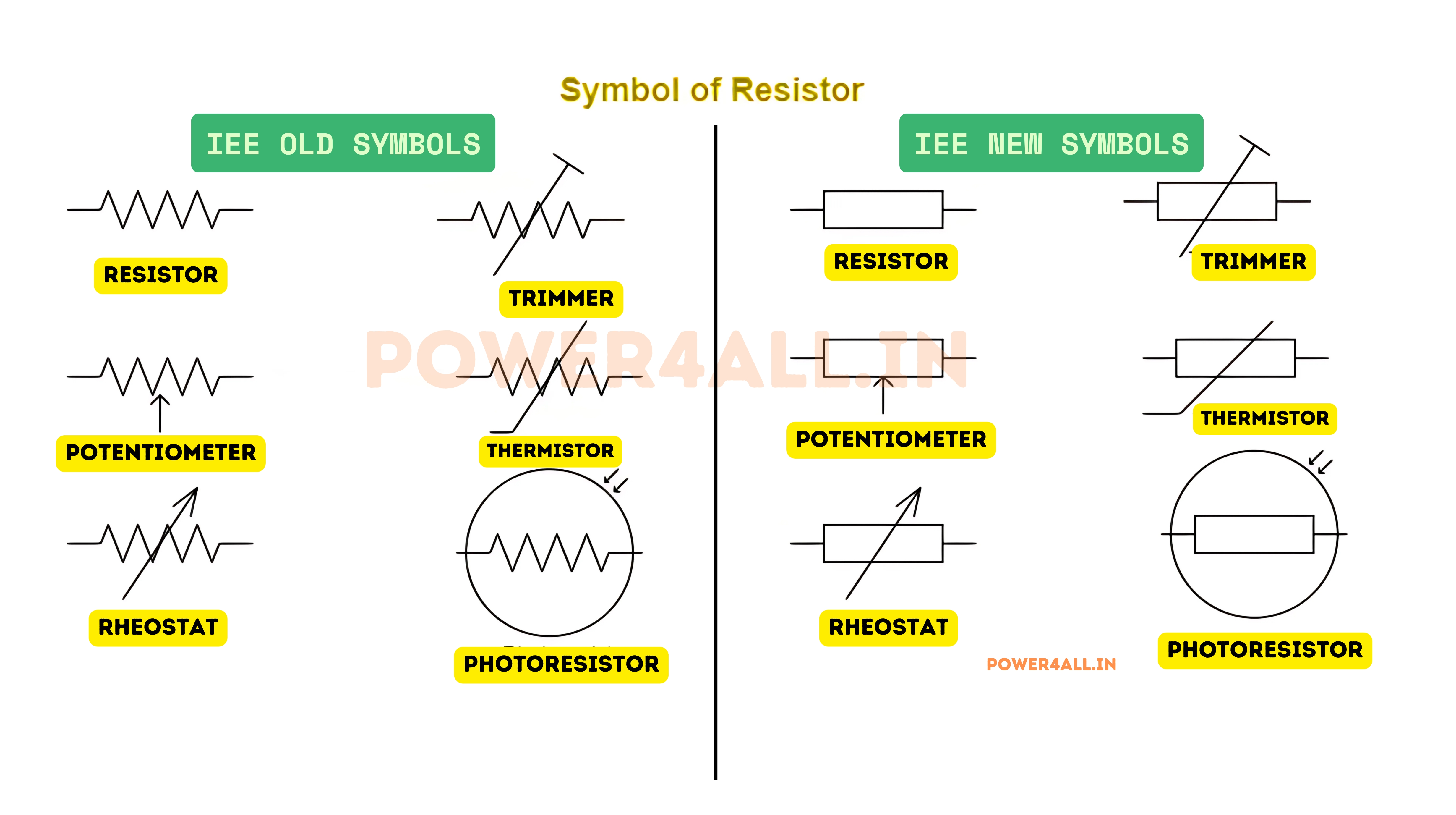

Circuit Symbols

- American (ANSI): Zigzag line pattern

- International (IEC): Rectangle with connecting lines

- Variable resistor: Arrow through symbol

- Photoresistor: Symbol with light arrows

- Thermistor: Symbol with temperature notation

Units of Measurement

- Ohm (Ω): Basic unit of resistance

- Kiloohm (kΩ): 1,000 ohms

- Megohm (MΩ): 1,000,000 ohms

- Milliohm (mΩ): 0.001 ohms

- Named after: Georg Simon Ohm, German physicist

Everyday Resistor Examples

- LED current limiting: 220Ω resistor protects LED from burning out

- Volume control: Variable resistor (potentiometer) in audio equipment

- Heating element: Low-value, high-power resistor in electric heaters

- Pull-up resistor: 10kΩ resistor ensures digital signals stay high

- Temperature sensor: Thermistor changes resistance with temperature

- Light sensor: Photoresistor varies with light intensity

Did You Know?

The first resistors were made from carbon powder mixed with clay and baked into ceramic tubes. Modern resistors can be as small as a grain of sand (surface mount) or as large as a brick (high-power applications), with resistance values ranging from fractions of an ohm to billions of ohms!

Resistor Fundamentals: How They Work

Understanding how resistors actually work involves exploring the atomic-level interactions that create resistance, the materials used in construction, and the fundamental principles that govern their behavior in electrical circuits.

The Physics of Resistance

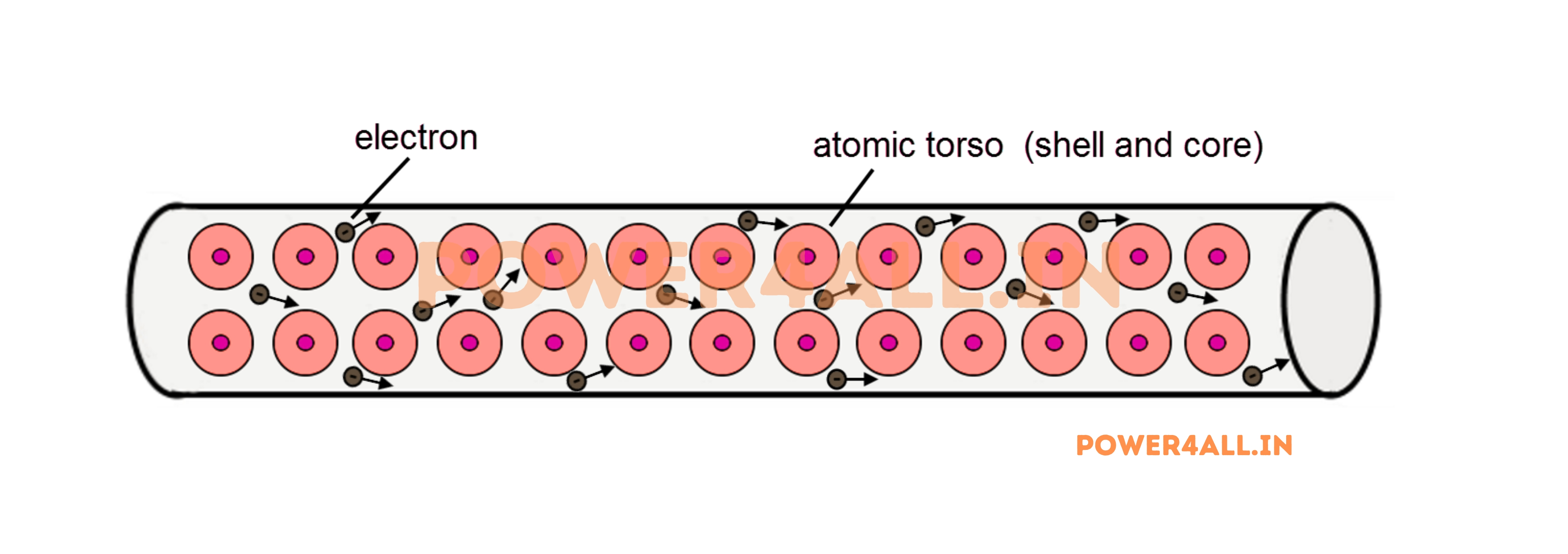

What Creates Electrical Resistance?

Resistance occurs when moving electrons collide with atoms in a material. These collisions convert some electrical energy into heat energy, which is why resistors get warm when current flows through them.

Microscopic View of Resistance

R = ρ × L / A

Resistance = Resistivity × Length / Cross-sectional Area

Factors Affecting Resistance

| Factor | Effect on Resistance | Why This Happens | Practical Example |

|---|---|---|---|

| Material Type | Different materials have vastly different resistance | Atomic structure affects electron mobility | Copper (low) vs Glass (very high) |

| Length | Longer = Higher resistance | More material = more collisions | 100ft vs 10ft wire |

| Cross-section | Thicker = Lower resistance | More paths for electron flow | Thick vs thin wire |

| Temperature | Usually higher temp = higher resistance | More atomic vibration = more collisions | Cold vs hot filament bulb |

Resistor Construction Materials

Carbon-Based Resistors

Most common and economical option

Carbon Composition

- Material: Carbon powder mixed with ceramic binder

- Construction: Molded into cylindrical shape

- Tolerance: ±5% to ±20% typical

- Advantages: Low cost, available in many values

- Disadvantages: Temperature sensitive, noisy

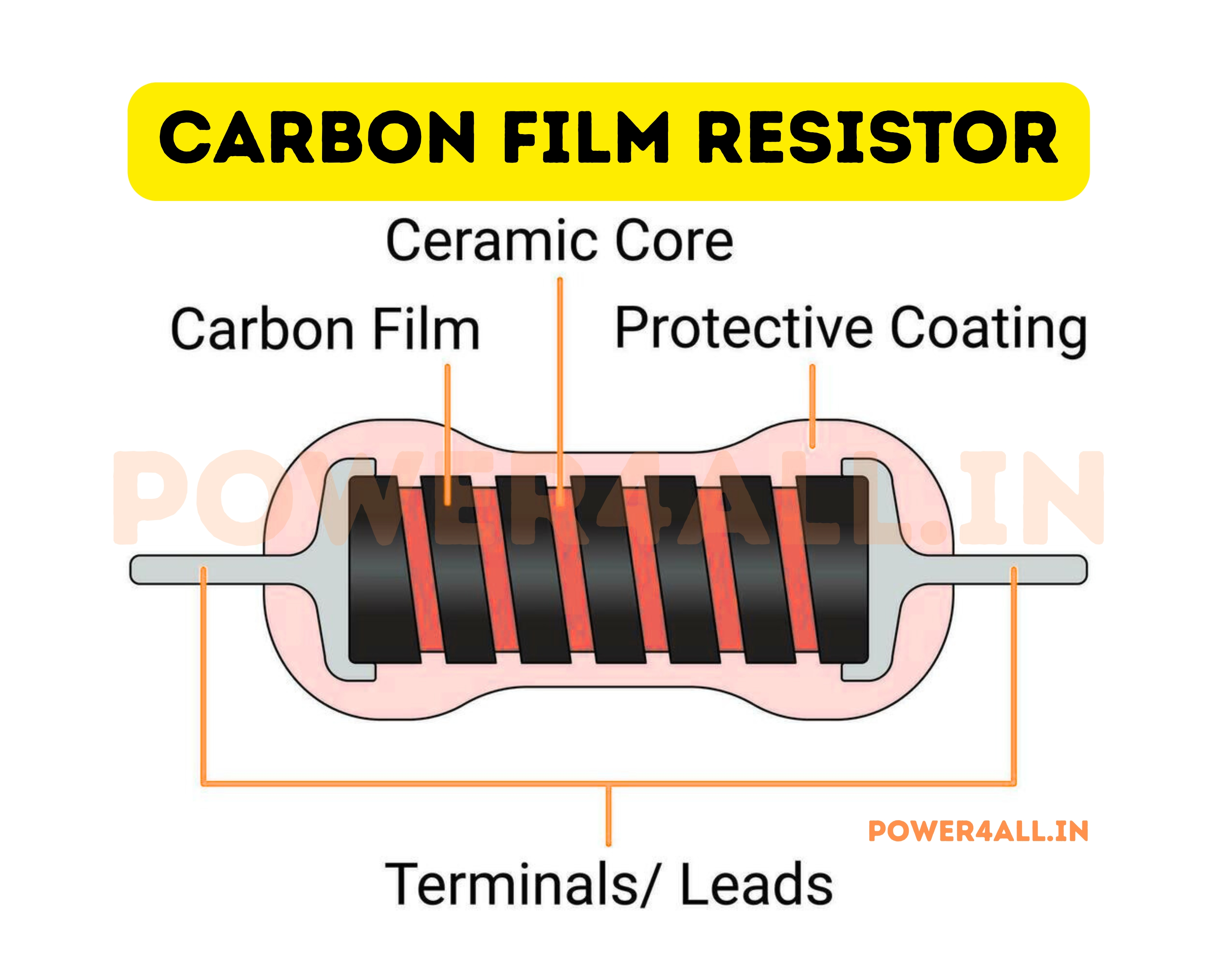

Carbon Film

- Material: Thin carbon film on ceramic core

- Tolerance: ±1% to ±5% typical

- Better performance: More stable than composition

- Applications: General purpose circuits

Metal-Based Resistors

Higher precision and stability

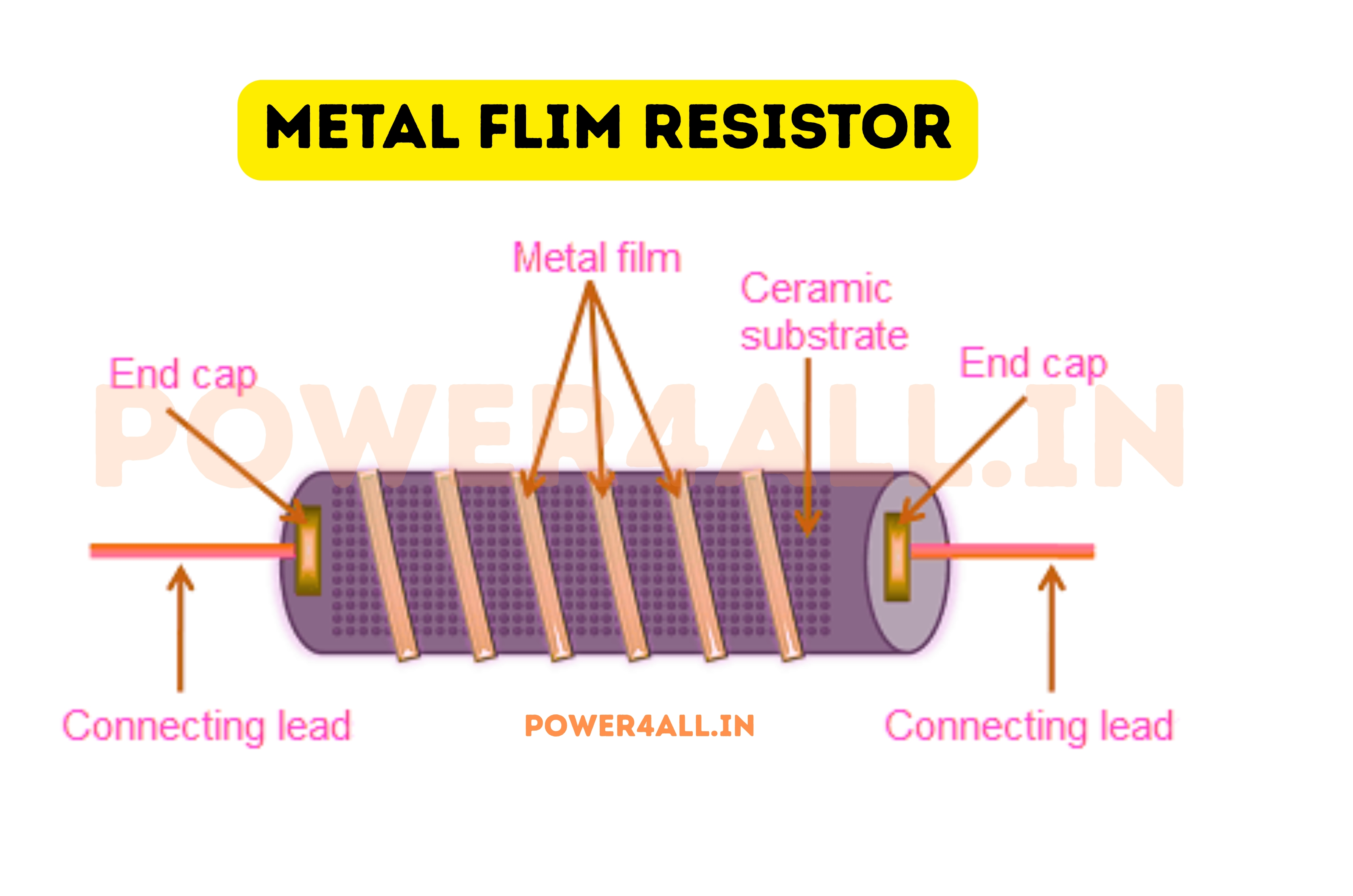

Metal Film

- Material: Thin metal alloy film (nichrome, tantalum)

- Tolerance: ±0.1% to ±1% achievable

- Temperature coefficient: Very low (stable)

- Noise level: Very low electrical noise

- Applications: Precision circuits, instrumentation

Metal Oxide

- Material: Metal oxide film on ceramic

- Power handling: Higher than metal film

- Temperature range: Excellent high-temp performance

- Applications: Power supplies, automotive

Wire Wound Resistors

High power and precision applications

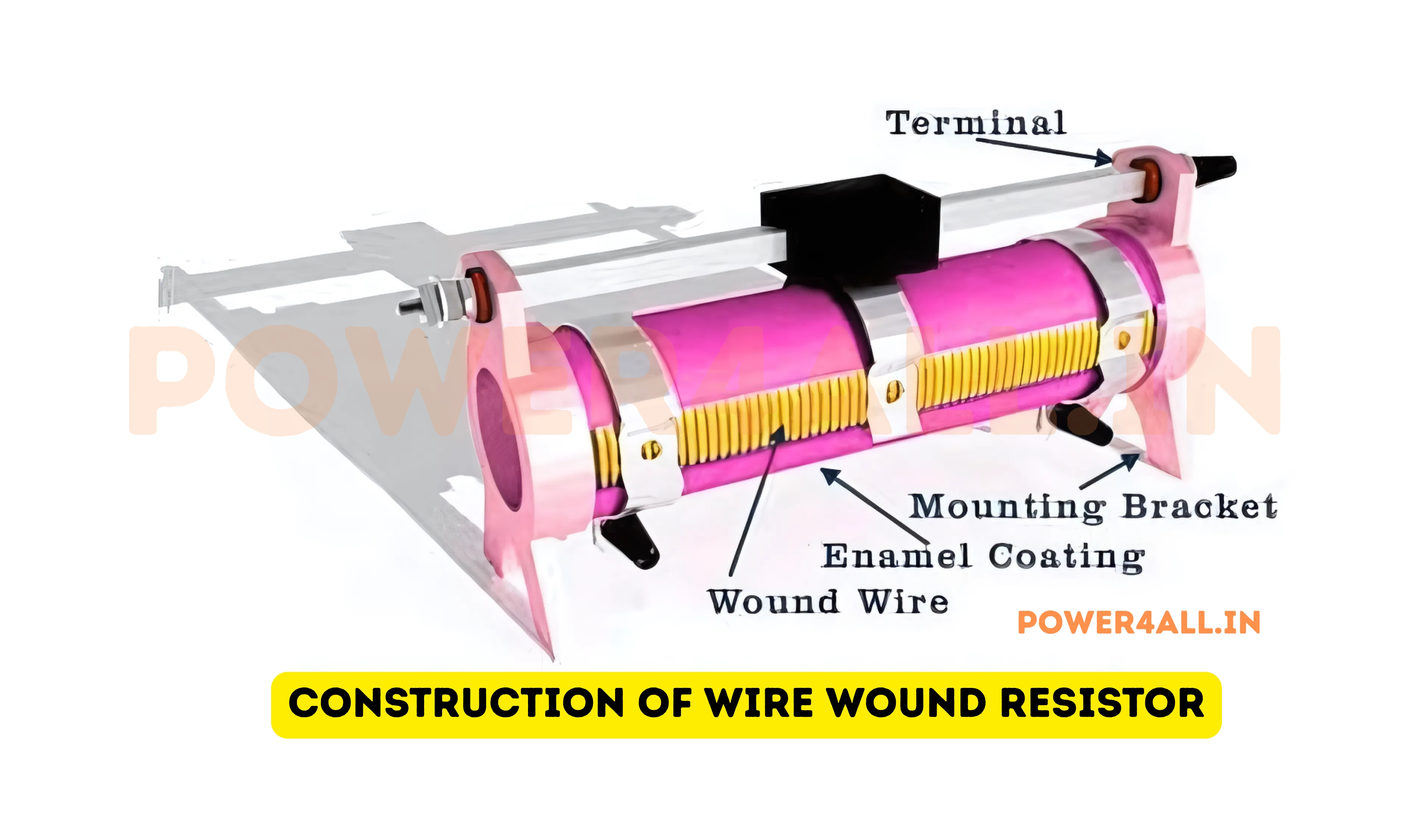

Construction Details

- Material: Resistance wire wound on ceramic core

- Wire types: Nichrome, constantan, manganin

- Power rating: 1W to thousands of watts

- Precision: ±0.01% achievable

- Limitation: Inductive at high frequencies

Specialty Types

- Precision wire wound: Laboratory standards

- Power wire wound: High wattage applications

- Non-inductive: Bifilar winding for RF use

- Adjustable: Variable tap positions

Temperature Effects on Resistance

How Temperature Changes Affect Resistor Performance

Temperature significantly affects resistor values. This effect is quantified by the Temperature Coefficient of Resistance (TCR), measured in parts per million per degree Celsius (ppm/°C).

R(T) = R₀ × [1 + α(T - T₀)]

Resistance at temperature T, where α is the temperature coefficient

| Resistor Type | Temperature Coefficient | Change per 100°C | Applications |

|---|---|---|---|

| Carbon composition | -800 to -1200 ppm/°C | -8% to -12% | Non-critical circuits |

| Carbon film | -200 to -800 ppm/°C | -2% to -8% | General purpose |

| Metal film | ±50 to ±200 ppm/°C | ±0.5% to ±2% | Precision circuits |

| Wire wound | ±20 to ±50 ppm/°C | ±0.2% to ±0.5% | High precision |

Temperature Effect Example

1kΩ metal film resistor (±100 ppm/°C) temperature change from 25°C to 125°C:

- Temperature change: ΔT = 125°C - 25°C = 100°C

- Resistance change: ΔR = 1000Ω × 100 ppm/°C × 100°C = 10Ω

- New resistance: R = 1000Ω + 10Ω = 1010Ω

- Percentage change: 1% increase

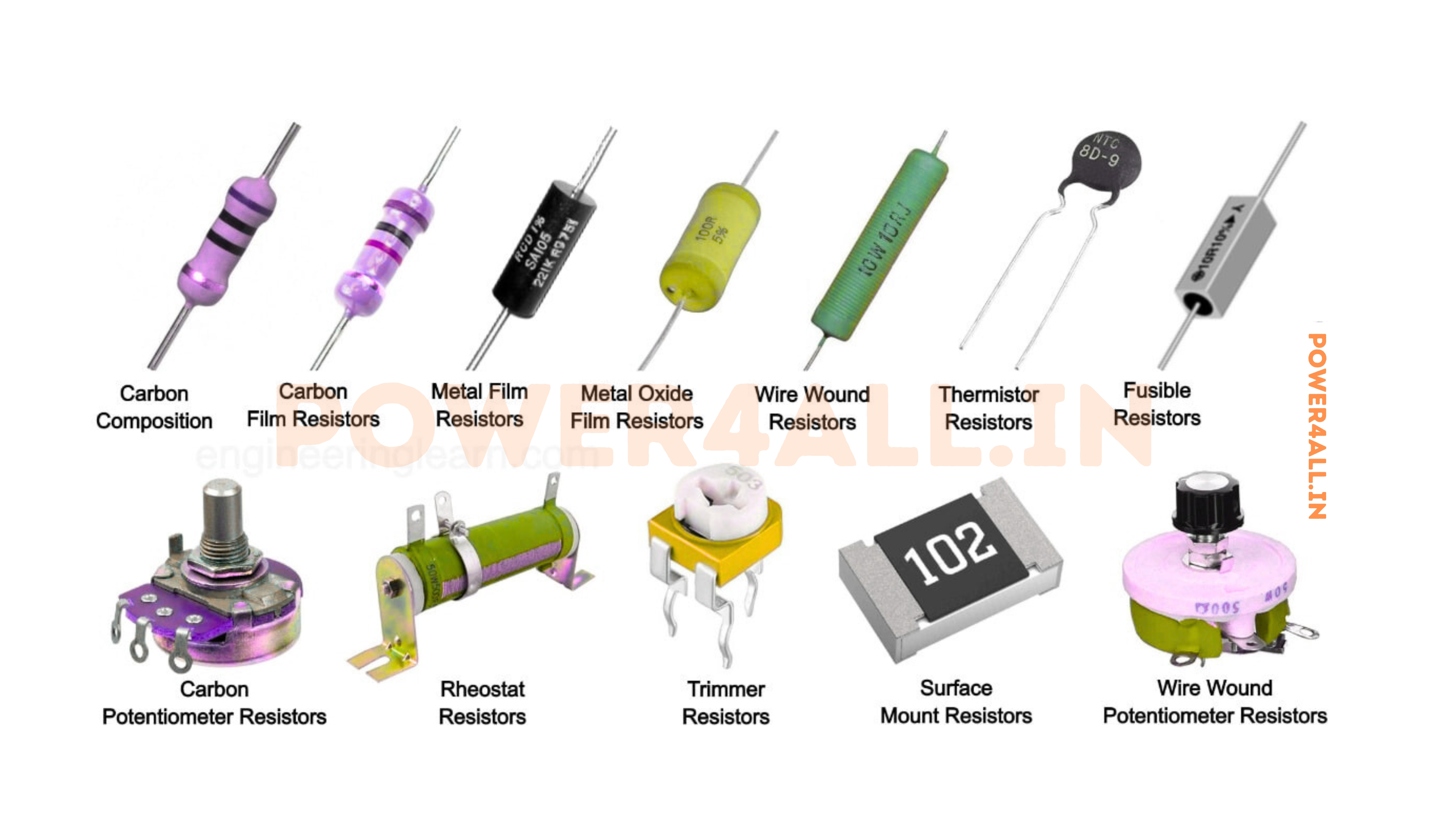

Types of Resistors: Complete Classification

Resistors come in many different types, each designed for specific applications and requirements. Understanding the various types helps in selecting the right resistor for your particular need, whether it's precision measurement, high power handling, or special environmental conditions.

Fixed Value Resistors

Through-Hole Resistors

Traditional resistors with leads for PCB mounting

Standard Sizes and Power Ratings

- 1/8 Watt (0.125W): 3-4mm body, general electronics

- 1/4 Watt (0.25W): 6mm body, most common size

- 1/2 Watt (0.5W): 8-9mm body, higher power needs

- 1 Watt: 11mm body, power supply circuits

- 2-5 Watts: Larger bodies, heat dissipation

Advantages

- Easy to handle and identify

- Color code clearly visible

- Good for prototyping

- Replaceable in circuits

- Lower cost than surface mount

Common Applications

- Hobby electronics and DIY projects

- Educational circuit boards

- Prototype development

- Repair and replacement work

- Low-volume production

Surface Mount Resistors (SMD)

Tiny resistors for modern electronics

Standard SMD Sizes

- 0201: 0.02" × 0.01" (0.6mm × 0.3mm)

- 0402: 0.04" × 0.02" (1.0mm × 0.5mm)

- 0603: 0.06" × 0.03" (1.6mm × 0.8mm)

- 0805: 0.08" × 0.05" (2.0mm × 1.25mm)

- 1206: 0.12" × 0.06" (3.2mm × 1.6mm)

Advantages

- Extremely compact size

- Lower parasitic inductance

- Automated assembly friendly

- Better high-frequency performance

- Cost effective in volume

Where You Find Them

- Smartphones and tablets

- Computer motherboards

- Automotive electronics

- IoT devices and sensors

- High-density circuit boards

Power Resistors

High wattage resistors for power applications

Power Ratings and Constructions

- 5-10 Watts: Ceramic housed, finned heat sinks

- 25-50 Watts: Aluminum housed, bolt mounting

- 100+ Watts: Liquid cooled, fan cooled options

- Kilowatt range: Grid resistors, load banks

Special Features

- Excellent heat dissipation

- Low temperature rise

- Robust construction

- High current capability

- Industrial mounting options

High Power Applications

- Motor start/brake resistors

- Load testing equipment

- Power supply bleeder resistors

- Heating elements

- Dynamic braking systems

Variable Resistors

Adjustable and Variable Resistance Components

Potentiometers (Pots)

Three-terminal variable resistors used for voltage division and user controls. The resistance between the center terminal and either end can be adjusted by turning a shaft or sliding a control.

Rotary Potentiometers

- Linear taper: Resistance changes proportionally

- Logarithmic taper: For audio volume controls

- Multi-turn: 10+ turns for precision adjustment

- Ganged: Multiple pots on one shaft

- Applications: Volume, tone, tuning controls

Slide Potentiometers

- Linear motion: Sliding control instead of rotary

- Visual feedback: Position easily seen

- Motorized versions: Computer controlled

- Precision types: Laboratory instruments

- Applications: Audio mixers, test equipment

Rheostats

Two-terminal variable resistors used to control current in a circuit. Unlike potentiometers, rheostats are connected in series with the load.

Rheostat Applications

- Light dimmers: Control incandescent bulb brightness

- Motor speed control: DC motor speed adjustment

- Heater control: Temperature adjustment

- Laboratory power supplies: Current limiting

Trimpots (Trimmer Potentiometers)

Small, preset variable resistors used for one-time or infrequent adjustments during manufacturing or servicing.

| Type | Adjustment Method | Typical Use | Adjustment Frequency |

|---|---|---|---|

| Cermet trimpot | Screwdriver adjustment | Circuit calibration | Set once during production |

| Carbon trimpot | Screwdriver or thumb wheel | Bias adjustment | Occasional service adjustment |

| Multi-turn trimpot | Precision screw drive | Precision calibration | Factory calibration only |

Special Purpose Resistors

Thermistors

Temperature-sensitive resistors

Types and Characteristics

- NTC (Negative Temperature Coefficient): Resistance decreases with temperature

- PTC (Positive Temperature Coefficient): Resistance increases with temperature

- Temperature range: -55°C to +200°C typical

- Sensitivity: Much higher than standard resistors

Thermistor Applications

- Temperature measurement and control

- Inrush current limiting (PTC)

- Temperature compensation circuits

- Digital thermometers

- Automotive temperature sensors

Photoresistors (LDR)

Light-dependent resistors

Operating Principles

- Light sensitivity: Resistance decreases with light intensity

- Material: Cadmium sulfide (CdS) most common

- Response time: Milliseconds to seconds

- Resistance range: MΩ in dark to kΩ in light

LDR Applications

- Automatic street lighting

- Camera light meters

- Security systems

- Display brightness control

- Solar tracking systems

Varistors (VDR)

Voltage-dependent resistors

Protection Characteristics

- Normal operation: Very high resistance

- Overvoltage condition: Resistance drops dramatically

- Clamping voltage: Limits voltage to safe levels

- Self-resetting: Returns to high resistance automatically

Varistor Applications

- Surge protection in power supplies

- Lightning protection systems

- Motor protection circuits

- Telecommunication equipment

- Automotive electronics protection

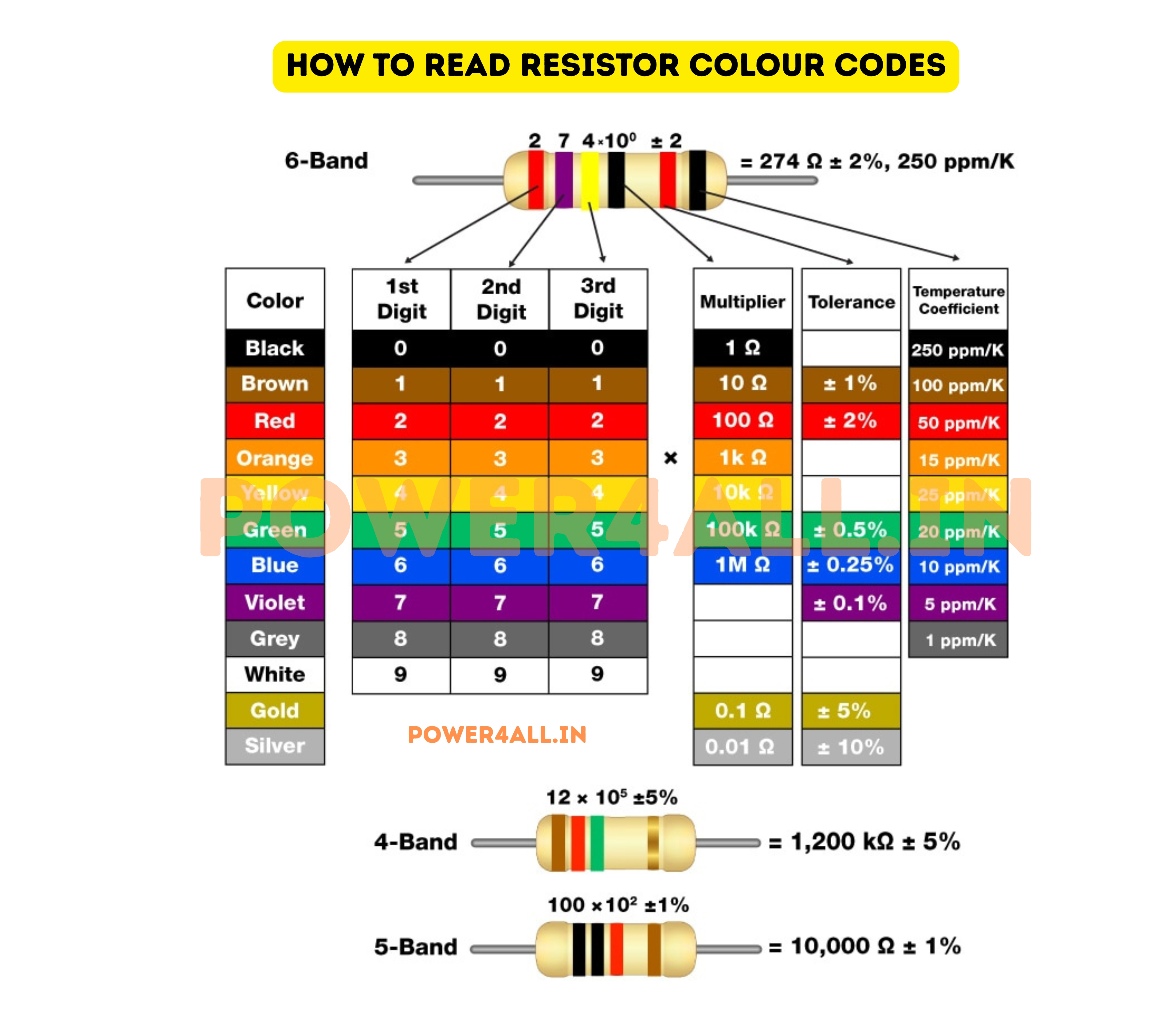

Resistor Color Code System: Reading Resistor Values

The resistor color code is a standardized system for indicating the resistance value and tolerance of through-hole resistors. Learning to read color codes is essential for working with electronics, as it allows you to quickly identify resistor values without needing measurement equipment.

Standard Color Code Chart

| Color | Digit Value | Multiplier | Tolerance | Color Sample |

|---|---|---|---|---|

| Black | 0 | ×1 (10⁰) | - | Black |

| Brown | 1 | ×10 (10¹) | ±1% | Brown |

| Red | 2 | ×100 (10²) | ±2% | Red |

| Orange | 3 | ×1,000 (10³) | - | Orange |

| Yellow | 4 | ×10,000 (10⁴) | - | Yellow |

| Green | 5 | ×100,000 (10⁵) | ±0.5% | Green |

| Blue | 6 | ×1,000,000 (10⁶) | ±0.25% | Blue |

| Violet | 7 | ×10,000,000 (10⁷) | ±0.1% | Violet |

| Grey | 8 | ×100,000,000 (10⁸) | ±0.05% | Grey |

| White | 9 | ×1,000,000,000 (10⁹) | - | White |

| Gold | - | ×0.1 (10⁻¹) | ±5% | Gold |

| Silver | - | ×0.01 (10⁻²) | ±10% | Silver |

Reading Different Band Configurations

4-Band Resistors

Most common configuration (±5% or ±10% tolerance)

Band Order (left to right)

Example: 4-Band Reading

Colors: Red, Violet, Orange, Gold

- Red (1st): 2

- Violet (2nd): 7

- Orange (3rd): ×1,000

- Gold (4th): ±5%

- Result: 27 × 1,000 = 27,000Ω = 27kΩ ±5%

5-Band Resistors

Precision resistors (±1% or better tolerance)

Band Order (left to right)

Example: 5-Band Reading

Colors: Brown, Black, Orange, Red, Brown

- Brown (1st): 1

- Black (2nd): 0

- Orange (3rd): 3

- Red (4th): ×100

- Brown (5th): ±1%

- Result: 103 × 100 = 10,300Ω = 10.3kΩ ±1%

6-Band Resistors

High precision with temperature coefficient

Band Order (left to right)

| 6th Band Color | Temperature Coefficient | Application |

|---|---|---|

| Brown | 100 ppm/°C | General precision |

| Red | 50 ppm/°C | High precision |

| Orange | 15 ppm/°C | Ultra precision |

| Yellow | 25 ppm/°C | Precision instruments |

Memory Aids for Color Codes

Popular Mnemonics for Remembering Color Codes

Classic Mnemonics

For colors 0-9 (Black, Brown, Red, Orange, Yellow, Green, Blue, Violet, Grey, White):

- "Big Brown Rabbits Often Yield Great Big Vegetables Grown Wild"

- "Bad Boys Race Our Young Girls But Violet Generally Wins"

- "Black Brown Red Orange Yellow Green Blue Violet Grey White" (direct memorization)

Practical Reading Tips

Orientation

Tolerance band (usually gold or silver) goes on the right. If unsure, the tolerance band is typically separated from other bands.

Good Lighting

Read colors under good lighting. Some colors (brown/red, orange/yellow) can be difficult to distinguish in poor light.

Verification

Use a multimeter to verify readings, especially when learning or when colors are unclear or faded.

Apps Available

Smartphone apps can help identify resistor values using camera recognition, useful for beginners or difficult-to-read resistors.

Common Reading Mistakes

- Wrong orientation: Reading from right to left instead of left to right

- Color confusion: Mistaking brown for red, or orange for yellow

- Band counting: Missing or misidentifying the number of bands

- Multiplier confusion: Forgetting that multiplier adds zeros, doesn't multiply digits

- Tolerance ignorance: Not considering the tolerance range in calculations

Ohm's Law & Resistor Calculations

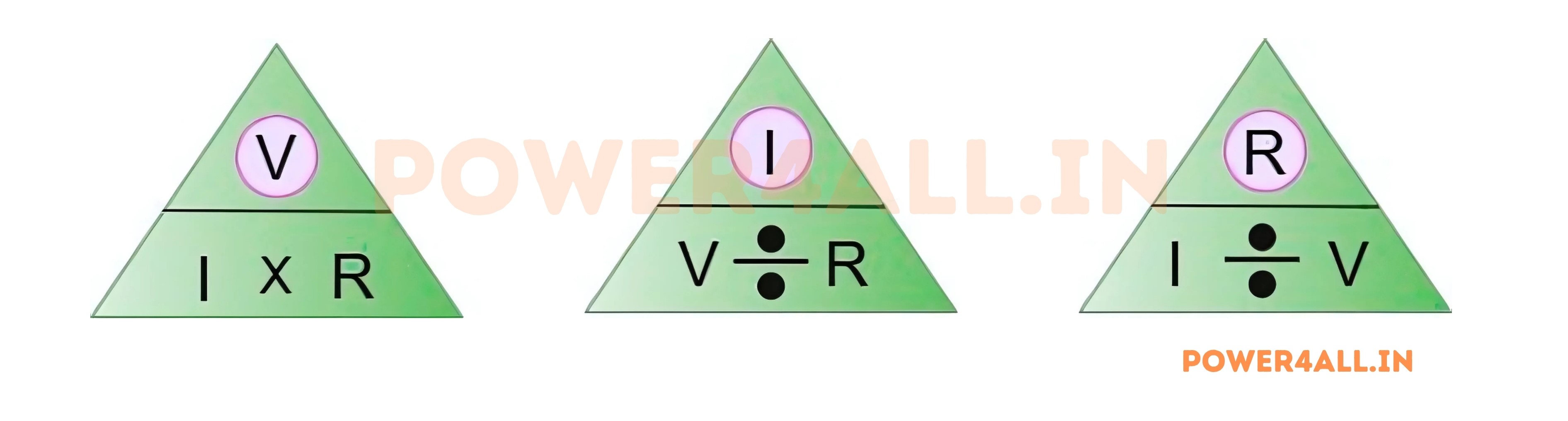

Ohm's Law is the fundamental relationship that governs how voltage, current, and resistance interact in electrical circuits. Understanding this law and its applications is essential for working with resistors and designing circuits that function safely and effectively.

The Fundamental Relationship

V = I × R

Voltage equals Current times Resistance

Derived Formulas

- Current: I = V / R

- Resistance: R = V / I

- Power: P = V × I = I²R = V²/R

Simple Example

9V battery connected to 1000Ω resistor:

- Current: I = V/R = 9V/1000Ω = 0.009A = 9mA

- Power: P = V²/R = 9²/1000 = 81/1000 = 0.081W = 81mW

- Safe operation: 81mW is well within a 1/4W resistor rating

Practical Calculation Examples

LED Current Limiting

Calculate resistor value to limit LED current

Result

Use a 470Ω, 1/4W resistor. This will give slightly more current (21.1mA) but within safe limits for most LEDs.

Voltage Divider Design

Create specific voltage from higher supply voltage

V_out = V_in × R2 / (R1 + R2)

Voltage divider formula

Power Dissipation Analysis

Ensure resistors can handle the power safely

Power Safety

Always derate power ratings by 50% or more for reliability. A 1/4W resistor should only handle about 0.125W in continuous operation.

Advanced Calculations

Complex Circuit Analysis with Multiple Resistors

Kirchhoff's Laws Application

For complex circuits with multiple resistors, we use Kirchhoff's Voltage Law (KVL) and Current Law (KCL) along with Ohm's Law.

Kirchhoff's Voltage Law (KVL)

Sum of voltage drops around any closed loop equals zero

ΣV = 0

Around any closed loop

Series Circuit Example

12V battery with 1kΩ and 2kΩ in series:

- Total resistance: 1kΩ + 2kΩ = 3kΩ

- Current: I = 12V/3kΩ = 4mA

- V across 1kΩ: 4mA × 1kΩ = 4V

- V across 2kΩ: 4mA × 2kΩ = 8V

- Check: 4V + 8V = 12V ✓

Kirchhoff's Current Law (KCL)

Current entering a node equals current leaving

ΣI_in = ΣI_out

At any node

Parallel Circuit Example

12V supply with 1kΩ and 2kΩ in parallel:

- Current through 1kΩ: I₁ = 12V/1kΩ = 12mA

- Current through 2kΩ: I₂ = 12V/2kΩ = 6mA

- Total current: I_total = 12mA + 6mA = 18mA

- Equivalent resistance: R_eq = 12V/18mA = 667Ω

- Check: 1/(1/1k + 1/2k) = 667Ω ✓

Temperature Effects on Calculations

Real-world resistor values change with temperature, affecting circuit calculations.

| Parameter | Cold (0°C) | Room Temp (25°C) | Hot (75°C) | Effect on Circuit |

|---|---|---|---|---|

| 1kΩ carbon resistor | 1020Ω | 1000Ω | 960Ω | ±4% current variation |

| 1kΩ metal film resistor | 1005Ω | 1000Ω | 995Ω | ±0.5% current variation |

| Current through resistor | 4.9mA | 5.0mA | 5.2mA | Proportional to resistance change |

Common Calculation Mistakes

Avoid These Common Errors

- Unit confusion: Mixing mA and A, kΩ and Ω in calculations

- Power miscalculation: Using wrong power formula for the given parameters

- Series/parallel confusion: Adding resistances incorrectly

- Tolerance ignorance: Not considering resistor tolerance in critical calculations

- Real-world factors: Ignoring temperature, aging, and tolerance effects

Power Ratings & Heat Management

Power rating is one of the most critical specifications for resistors, as it determines how much electrical power the resistor can safely dissipate as heat. Understanding power ratings, heat generation, and thermal management is essential for reliable circuit design and preventing component failure.

Understanding Power Dissipation

Why Resistors Generate Heat

When current flows through a resistor, electrical energy is converted to heat energy. This is not a byproduct or inefficiency - it's exactly how resistors work! The heat generation follows the fundamental power equations.

P = I²R = V²/R = V×I

Power dissipated as heat (in Watts)

Heat Generation Example

100Ω resistor with 1A current:

- Power: P = I²R = 1² × 100 = 100W

- Heat equivalent: Same as a 100W light bulb!

- Voltage drop: V = IR = 1A × 100Ω = 100V

- Temperature rise: Could exceed 500°C without cooling

- Conclusion: Needs proper heat sink and ventilation

Standard Power Ratings

| Power Rating | Physical Size | Typical Applications | Maximum Current* | Heat Considerations |

|---|---|---|---|---|

| 1/8 W (0.125W) | 3-4mm length | Low-power electronics, sensors | 11mA (1kΩ) | Minimal heating |

| 1/4 W (0.25W) | 6mm length | General electronics, indicators | 16mA (1kΩ) | Slight warming |

| 1/2 W (0.5W) | 8-9mm length | Power supplies, drivers | 22mA (1kΩ) | Noticeably warm |

| 1 W | 11mm length | Power circuits, current limiting | 32mA (1kΩ) | Hot to touch |

| 2-5 W | 15-20mm length | Power supplies, motor circuits | 45-71mA (1kΩ) | Requires heat sinking |

| 10+ W | Special packages | Power systems, heaters | 100+mA (1kΩ) | Active cooling needed |

*Maximum current values calculated for 1kΩ resistance using P = I²R at rated power

Derating and Safety Factors

Why You Should Never Use Full Power Rating

Using a resistor at its full power rating in continuous operation leads to high temperatures, shorter life, and potential failure. Proper engineering practice requires derating for reliability.

Recommended Derating Guidelines

50% Derating (Conservative)

Use only 50% of rated power for maximum reliability and long life. A 1W resistor should only dissipate 0.5W continuously.

70% Derating (Standard)

Industry standard for most applications. Provides good balance between component utilization and reliability.

Temperature Derating

Power rating decreases with ambient temperature. At 70°C ambient, most resistors can only handle 50% of their rated power.

Pulse vs Continuous

Resistors can handle higher power for short pulses. Continuous operation requires more conservative ratings.

| Application Type | Recommended Derating | Reason | Example |

|---|---|---|---|

| Critical systems | 50% or less | Maximum reliability required | Medical devices, aerospace |

| Commercial products | 60-70% | Balance cost vs reliability | Consumer electronics |

| High temperature environment | 40-50% | Reduced heat dissipation | Automotive under-hood |

| Pulse applications | 80-90% | Thermal mass absorbs heat | Switch-mode power supplies |

Derating Calculation Example

Need to dissipate 0.75W continuously in a 50°C environment:

- 50% derating: Need 0.75W ÷ 0.5 = 1.5W rated resistor

- Temperature derating: At 50°C, further reduce by 20%

- Final requirement: 1.5W ÷ 0.8 = 1.875W

- Selection: Choose 2W or 3W rated resistor

Heat Dissipation and Thermal Management

Natural Air Cooling

Simplest cooling method for low to medium power

Key Factors

- Surface area: Larger resistors dissipate heat better

- Orientation: Vertical mounting improves convection

- Spacing: Allow air circulation around components

- Enclosure ventilation: Provide air inlet/outlet

Natural Cooling Guidelines

- Space resistors at least 5mm apart

- Mount power resistors vertically when possible

- Keep hot components away from sensitive ICs

- Use larger PCB copper areas for heat spreading

Heat Sinks and Forced Air

Enhanced cooling for higher power applications

Heat Sink Types

- Aluminum extrusions: Cost-effective, good performance

- Finned heat sinks: Maximum surface area

- Thermal interface materials: Improve heat transfer

- Mounting hardware: Proper mechanical and thermal contact

R_thermal = ΔT / P

Thermal resistance = Temperature rise / Power

Liquid Cooling

Ultimate cooling for very high power applications

Applications

- Load testing: Kilowatt-level resistive loads

- Industrial systems: High-power motor controls

- Research equipment: Precision high-power circuits

- Grid applications: Utility-scale resistive loads

When to Use Liquid Cooling

Consider liquid cooling for continuous power dissipation above 50W per resistor, or when ambient temperatures exceed 40°C.

Temperature Rise and Safety

Safety Warning

Resistors operating at high power can reach temperatures exceeding 200°C (392°F). This can cause burns, ignite flammable materials, or damage nearby components. Always consider fire safety and component spacing in high-power designs.

Temperature Rise Estimation

Typical thermal resistance values for air-cooled resistors:

- 1/4W resistor: 300°C/W → 0.25W × 300 = 75°C rise

- 1W resistor: 100°C/W → 1W × 100 = 100°C rise

- 5W resistor: 50°C/W → 5W × 50 = 250°C rise

- With heat sink: Can reduce thermal resistance by 10× or more

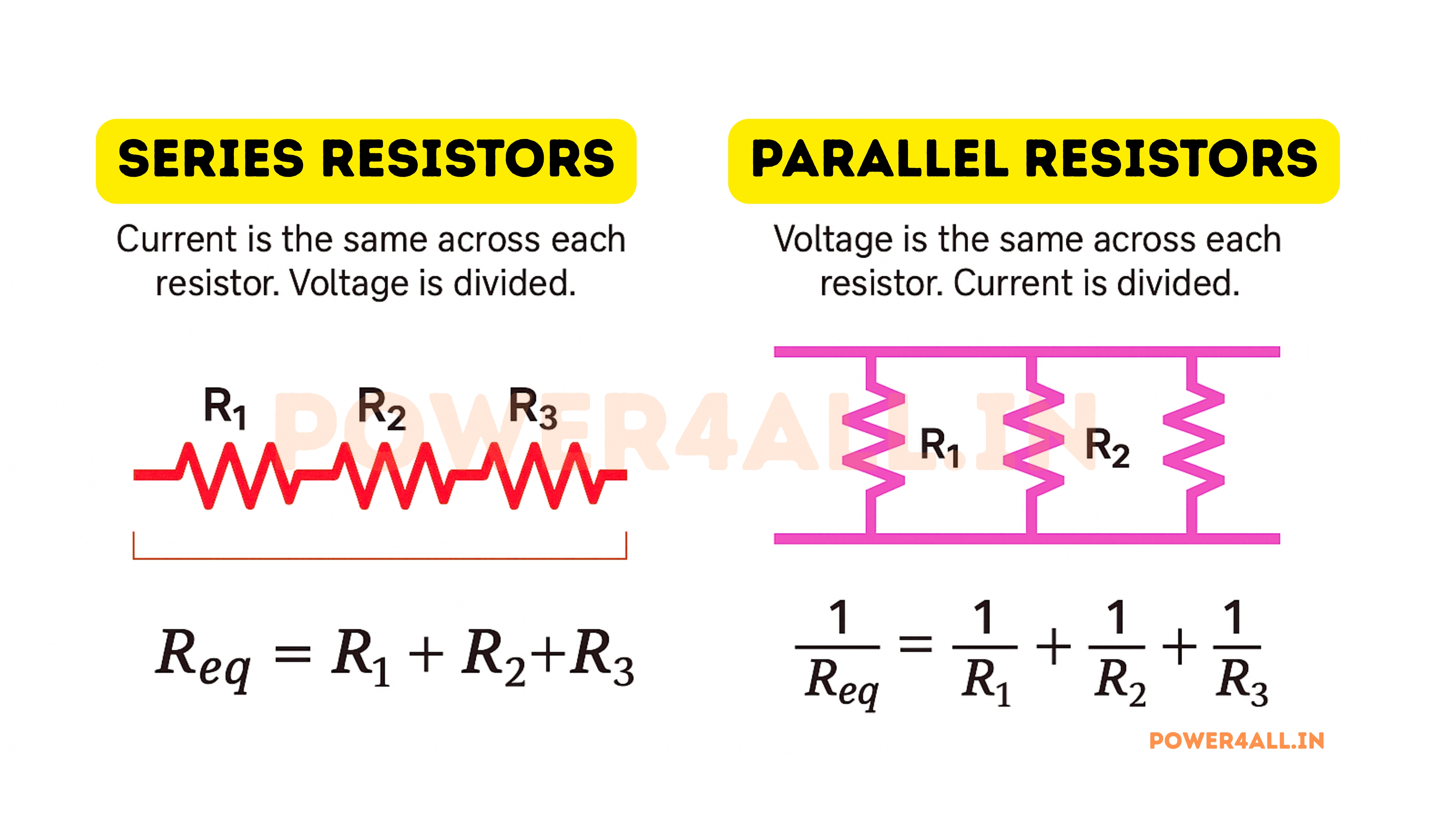

Series & Parallel Resistor Combinations

Understanding how resistors behave when connected in series and parallel is fundamental to circuit design. These combinations allow you to create precise resistance values, divide voltages, control currents, and increase power handling capability beyond what single resistors can provide.

Series Resistor Combinations

Series Connection Rules

In series connections, resistors are connected end-to-end in a single path. Current must flow through each resistor in sequence.

R_total = R1 + R2 + R3 + ...

Total resistance equals sum of individual resistances

Key Characteristics

- Same current: Identical current through all resistors

- Voltage divides: Voltage splits proportionally

- Power adds: Total power = sum of individual powers

- Higher total resistance: Always greater than largest individual resistor

Series Example

Three resistors: 100Ω, 220Ω, 330Ω in series with 12V:

- Total resistance: 100 + 220 + 330 = 650Ω

- Circuit current: I = 12V ÷ 650Ω = 18.5mA

- Voltage across 100Ω: 18.5mA × 100Ω = 1.85V

- Voltage across 220Ω: 18.5mA × 220Ω = 4.07V

- Voltage across 330Ω: 18.5mA × 330Ω = 6.08V

- Check: 1.85 + 4.07 + 6.08 = 12V ✓

Practical Series Applications

Voltage Dividers

Create specific voltages from higher supply voltage

V_out = V_in × R2/(R1+R2)

Output voltage from voltage divider

3.3V from 5V Supply

- Ratio needed: 3.3V/5V = 0.66

- Choose R1 = 1.7kΩ, R2 = 3.3kΩ

- Check: 5V × 3.3k/(1.7k+3.3k) = 3.3V ✓

- Current: 5V/5kΩ = 1mA (low power)

Current Limiting

Control current to sensitive components

LED Current Limiting Chain

3 LEDs in series with current limiting resistor:

- Supply voltage: 12V

- LED voltage drop: 3 × 2.1V = 6.3V

- Resistor voltage: 12V - 6.3V = 5.7V

- Desired current: 20mA

- Required resistor: 5.7V ÷ 20mA = 285Ω

- Use standard: 270Ω or 300Ω

High Voltage Applications

Distribute voltage stress across multiple resistors

High Voltage Divider

1000V measurement with 10:1 divider:

- R1 (high side): 9MΩ (900V across it)

- R2 (low side): 1MΩ (100V across it)

- Output: 100V for 1000V input

- Safety: Each resistor sees only portion of total voltage

Parallel Resistor Combinations

Parallel Connection Rules

In parallel connections, resistors are connected side-by-side with common connection points. Each resistor provides an alternate path for current.

1/R_total = 1/R1 + 1/R2 + 1/R3 + ...

Reciprocal formula for parallel resistance

Key Characteristics

- Same voltage: Identical voltage across all resistors

- Current divides: Current splits based on resistance

- Power adds: Total power = sum of individual powers

- Lower total resistance: Always less than smallest individual resistor

Parallel Example

Three resistors: 100Ω, 200Ω, 300Ω in parallel with 12V:

- 1/R_total = 1/100 + 1/200 + 1/300

- 1/R_total = 0.01 + 0.005 + 0.0033 = 0.0183

- R_total = 1/0.0183 = 54.6Ω

- Current through 100Ω: 12V ÷ 100Ω = 120mA

- Current through 200Ω: 12V ÷ 200Ω = 60mA

- Current through 300Ω: 12V ÷ 300Ω = 40mA

- Total current: 120 + 60 + 40 = 220mA

Practical Parallel Applications

When and Why to Use Parallel Resistors

Creating Non-Standard Values

Need 75Ω but only have 150Ω resistors

- Two 150Ω in parallel: R = 150Ω ÷ 2 = 75Ω ✓

- General rule: N identical resistors in parallel = R ÷ N

- Power benefit: Each resistor handles half the current

- Cost benefit: Use common values instead of special orders

Increasing Power Handling

| Configuration | Resistance | Power Rating | Current Capability | Use Case |

|---|---|---|---|---|

| Single 10Ω, 1W | 10Ω | 1W | 316mA | Basic application |

| Two 20Ω, 1W in parallel | 10Ω | 2W | 447mA | Higher power needed |

| Four 40Ω, 1W in parallel | 10Ω | 4W | 632mA | High current application |

Current Sharing and Load Distribution

Equal Current Sharing

Identical resistors in parallel share current equally, preventing any single resistor from being overloaded.

Redundancy

If one resistor fails open, others continue to carry current. Critical for safety applications.

Heat Distribution

Heat generation is spread across multiple components, improving thermal management.

Cost Optimization

Multiple low-power resistors often cost less than one high-power resistor.

Complex Combinations

Series-Parallel Networks and Advanced Calculations

Step-by-Step Analysis Method

Complex Network Example

Network: R1(100Ω) in series with [R2(200Ω) parallel with R3(300Ω)]

- Step 1: Calculate R2||R3 = (200×300)/(200+300) = 120Ω

- Step 2: Total = R1 + R2||R3 = 100Ω + 120Ω = 220Ω

- With 12V applied: Total current = 12V/220Ω = 54.5mA

- Voltage across R1: 54.5mA × 100Ω = 5.45V

- Voltage across parallel pair: 12V - 5.45V = 6.55V

- Current through R2: 6.55V/200Ω = 32.8mA

- Current through R3: 6.55V/300Ω = 21.8mA

Quick Parallel Formulas

| Configuration | Formula | Quick Calculation | Example |

|---|---|---|---|

| Two resistors | R = (R1×R2)/(R1+R2) | Product over sum | (100×200)/(100+200) = 66.7Ω |

| Equal resistors | R = R_value/N | Value divided by quantity | 4×100Ω = 100Ω/4 = 25Ω |

| One much smaller | R ≈ R_smallest | Dominated by smallest | 1Ω||1MΩ ≈ 1Ω |

Practical Applications: Resistors in Real Circuits

Resistors are found in virtually every electronic device, performing essential functions from simple current limiting to complex signal processing. Understanding their practical applications helps bridge the gap between theory and real-world circuit design.

Basic Circuit Functions

LED Current Limiting

Protecting LEDs from overcurrent damage

Why LEDs Need Current Limiting

- Exponential I-V curve: Small voltage changes cause large current changes

- No internal resistance: LEDs have virtually no current limiting

- Temperature sensitive: LED resistance decreases as they heat up

- Destructive failure: Overcurrent permanently damages LED junction

LED Resistor Calculation

Red LED: Forward voltage = 1.8V, Desired current = 15mA, Supply = 5V

- Resistor voltage: 5V - 1.8V = 3.2V

- Resistor value: R = 3.2V ÷ 0.015A = 213Ω

- Standard value: Use 220Ω (closest standard)

- Actual current: 3.2V ÷ 220Ω = 14.5mA (acceptable)

- Power rating: P = I²R = (0.0145)² × 220 = 46mW

- Resistor choice: 1/8W resistor is adequate

Pull-up and Pull-down Resistors

Ensuring digital signals have defined logic levels

Pull-up Resistors

- Function: Pull signal to logic HIGH when not driven

- Typical values: 1kΩ to 100kΩ

- Applications: Reset buttons, I2C bus, open-drain outputs

- Connection: Between signal line and VCC

Pull-down Resistors

- Function: Pull signal to logic LOW when not driven

- Typical values: 1kΩ to 100kΩ

- Applications: Switch inputs, enable pins

- Connection: Between signal line and ground

Pull-up Resistor Value Selection

Factors to consider:

- Too low (1kΩ): High power consumption when pulled low

- Too high (1MΩ): Slow switching, noise susceptible

- Typical choice (10kΩ): Good balance for most applications

- I2C bus (4.7kΩ): Standard value for I2C communication

Voltage Dividers for Sensing

Converting sensors to usable voltage ranges

Common Sensor Applications

- Potentiometer position: Variable voltage output

- Thermistor temperature: Temperature to voltage conversion

- Photoresistor light: Light intensity to voltage

- Battery monitoring: Scale down battery voltage

Temperature Sensor Circuit

10kΩ NTC thermistor with 10kΩ fixed resistor:

- At 25°C: Thermistor = 10kΩ, Output = 2.5V

- At 0°C: Thermistor = 32kΩ, Output = 1.2V

- At 50°C: Thermistor = 3.6kΩ, Output = 3.7V

- ADC input: 0-5V range covers wide temperature span

Advanced Circuit Applications

Sophisticated Uses in Modern Electronics

Operational Amplifier Circuits

Op-Amp Gain Setting

Precision resistors determine amplifier gain

Gain = 1 + (Rf / Rin)

Non-inverting amplifier gain formula

Precision Gain Example

Need exact 10× gain for sensor amplifier:

- Required: Gain = 10, so Rf/Rin = 9

- Choose Rin = 10kΩ, Rf = 90kΩ

- Tolerance effect: ±1% resistors give ±2% gain accuracy

- Temperature drift: Matched resistors cancel temperature effects

Active Filters

RC networks create frequency-selective circuits

fc = 1 / (2π × R × C)

Cutoff frequency for RC filter

Audio Filter Design

Low-pass filter for 1kHz cutoff:

- Choose C = 100nF (common value)

- Calculate R = 1/(2π×1000×100×10⁻⁹) = 1.59kΩ

- Use standard 1.6kΩ resistor

- Actual fc = 995Hz (close enough)

Digital Circuit Applications

| Application | Typical Value | Purpose | Critical Parameters |

|---|---|---|---|

| Current limiting for GPIOs | 220Ω - 1kΩ | Protect microcontroller pins | Maximum current rating |

| Crystal oscillator feedback | 1MΩ - 10MΩ | Bias crystal in linear region | Low leakage, stability |

| UART/SPI termination | 120Ω | Match transmission line impedance | Precision tolerance |

| Reset circuits | 10kΩ pull-up | Ensure defined reset state | Power consumption vs speed |

| LED indicators | 220Ω - 470Ω | Limit LED current | Power rating for continuous use |

Power Supply and Protection Circuits

Bleeder Resistors

High-value resistors across filter capacitors safely discharge stored energy when power is removed, preventing electric shock hazards.

Current Sensing

Low-value, precision shunt resistors (milliohms) measure current by monitoring voltage drop using Ohm's Law.

Thermal Compensation

Temperature-matched resistor networks compensate for thermal drift in precision circuits like voltage references.

Surge Limiting

High-power resistors limit inrush current during power-up, protecting sensitive components from startup surges.

Industry-Specific Applications

Specialized Uses Across Different Industries

Automotive Electronics

- Engine control units: Sensor conditioning, actuator control

- Safety systems: ABS, airbag deployment timing

- Comfort features: Climate control, seat heating

- Infotainment: Audio processing, display backlighting

- Charging systems: Current monitoring, protection

Automotive Requirements

Must withstand -40°C to +125°C, vibration, moisture, and electrical transients. AEC-Q200 qualified components preferred.

Medical Devices

- Patient monitoring: ECG, blood pressure, temperature sensors

- Imaging equipment: X-ray, MRI, ultrasound signal processing

- Therapeutic devices: Pacemakers, defibrillators, stimulators

- Diagnostic tools: Blood analyzers, glucose meters

- Safety isolation: Patient protection from electrical hazards

Medical Requirements

Ultra-high reliability, biocompatibility, regulatory compliance (FDA, CE marking), and fail-safe operation are mandatory.

Telecommunications

- Signal conditioning: Line drivers, receivers, equalizers

- Impedance matching: 50Ω, 75Ω transmission lines

- Power distribution: DC-DC converters, current sharing

- Protection circuits: Surge, overvoltage, ESD protection

- Filtering: EMI suppression, signal bandwidth limiting

Telecom Precision Example

75Ω coaxial cable termination:

- Requires exactly 75Ω ±1% for minimum reflections

- Temperature coefficient <100ppm/°C for stability

- Low noise for signal integrity

- High frequency performance to GHz range

Resistor Selection Guide: Choosing the Right Component

Selecting the right resistor for your application involves considering multiple factors beyond just resistance value. This comprehensive guide will help you make informed decisions based on your specific requirements, ensuring optimal performance and reliability.

Selection Criteria Matrix

| Application Type | Recommended Type | Tolerance | Power Rating | Special Requirements | Cost Impact |

|---|---|---|---|---|---|

| General purpose hobby | Carbon film, 1/4W | ±5% | 50% derating | None | Lowest cost |

| Digital circuits | Metal film or thick film | ±1% to ±5% | Low power typically | Low noise, fast response | Low to medium |

| Precision analog | Metal film, thin film | ±0.1% to ±1% | Conservative derating | Low TCR, matched pairs | Medium to high |

| RF/High frequency | Thin film, chip resistors | ±1% to ±5% | Based on power | Low inductance/capacitance | Medium to high |

| High power | Wire wound, metal oxide | ±1% to ±5% | Significant derating | Heat sinking, cooling | High |

| Automotive/Industrial | Metal film, thick film | ±1% to ±5% | Wide temp derating | AEC-Q200, wide temp range | Medium to high |

Step-by-Step Selection Process

Detailed Selection Factors

Tolerance Requirements

How accurate does your resistor need to be?

Tolerance Impact on Circuit Performance

- ±20% (Silver): Very old or low-cost applications

- ±10% (Silver): Non-critical applications, LEDs

- ±5% (Gold): General purpose, most common choice

- ±1% (Brown): Better accuracy for filters, dividers

- ±0.5% (Green): Precision measurement circuits

- ±0.1% (Violet): High-precision instrumentation

Tolerance Selection Example

Voltage divider for 3.3V from 5V (66% ratio):

- ±5% resistors: Output range 3.0V to 3.6V

- ±1% resistors: Output range 3.2V to 3.4V

- For 3.3V ±5% spec: Need ±1% resistors minimum

- Cost impact: ±1% costs ~50% more than ±5%

Temperature Considerations

How will temperature affect your circuit?

Temperature Coefficient (TCR) Impact

| Resistor Type | TCR (ppm/°C) | 100°C Change Effect |

|---|---|---|

| Carbon composition | -800 to -1200 | -8% to -12% |

| Carbon film | -200 to -800 | -2% to -8% |

| Metal film | ±50 to ±200 | ±0.5% to ±2% |

| Precision metal film | ±25 to ±50 | ±0.25% to ±0.5% |

Temperature Design Rule

For precision circuits operating over wide temperature ranges, temperature coefficient often matters more than initial tolerance. Choose TCR specification carefully.

Frequency Response

High-frequency behavior and parasitic effects

Parasitic Elements

- Parasitic inductance: Wire wound resistors have highest

- Parasitic capacitance: Limits high-frequency performance

- Skin effect: Reduces effective resistance at high frequencies

- Thermal noise: Johnson noise increases with resistance and temperature

f_corner = 1/(2π√LC)

Self-resonant frequency from parasitic L and C

High-Frequency Guidelines

- DC to 1MHz: Standard resistors work fine

- 1-100MHz: Use film resistors, avoid wire wound

- 100MHz-1GHz: Thin film chip resistors preferred

- >1GHz: Specialized RF resistors required

Standard Values and E-Series

Understanding Standard Resistor Values

Resistors are manufactured in standard values based on E-series (derived from Renard series). This system ensures adequate value coverage while minimizing the number of different values needed.

Common E-Series Values

| Series | Tolerance | Values per Decade | Example Values (1-10 range) |

|---|---|---|---|

| E6 | ±20% | 6 | 1.0, 1.5, 2.2, 3.3, 4.7, 6.8 |

| E12 | ±10% | 12 | 1.0, 1.2, 1.5, 1.8, 2.2, 2.7, 3.3, 3.9, 4.7, 5.6, 6.8, 8.2 |

| E24 | ±5% | 24 | 1.0, 1.1, 1.2, 1.3, 1.5, 1.6, 1.8, 2.0, 2.2, 2.4, 2.7, 3.0... |

| E48 | ±2% | 48 | More intermediate values available |

| E96 | ±1% | 96 | Very fine resolution for precision applications |

Finding Closest Standard Values

Selection Strategy

Need 1347Ω resistor for LED current limiting:

- E24 series closest: 1300Ω (3.5% low) or 1500Ω (11.4% high)

- Choose 1300Ω: Slightly higher LED current, usually acceptable

- Or choose 1500Ω: Lower LED current, safer for LED

- Check current: Verify actual current is within LED specifications

Series/Parallel Combinations for Exact Values

Series Combination

Add standard values to get exact resistance. Example: 1347Ω = 1000Ω + 330Ω + 18Ω (using E24 values).

Parallel Combination

Use parallel formula for values between standards. Example: 750Ω = 1500Ω || 1500Ω.

Online Calculators

Many online tools can find optimal combinations of standard values to achieve target resistance.

Cost Consideration

Single precision resistor often costs less than multiple standard values, especially in production.

Cost Optimization Strategies

Smart Cost Management

- Standardize on common values: E12 or E24 series for volume discounts

- Choose appropriate tolerance: Don't over-specify precision unnecessarily

- Consider package type: SMD often cheaper in volume than through-hole

- Plan for second sources: Ensure multiple suppliers for critical values

- Volume breaks: Significant price reduction at 1K, 10K, 100K quantities

- Obsolescence planning: Choose mainstream parts with long-term availability

Testing & Troubleshooting Resistors

Testing resistors properly and troubleshooting resistor-related problems are essential skills for anyone working with electronics. This section covers measurement techniques, common failure modes, and systematic troubleshooting approaches.

Basic Resistance Measurement

Using a Digital Multimeter

The most common tool for resistor testing

Proper Measurement Technique

Common Measurement Errors

- Parallel paths: Other circuit components affect reading

- Body resistance: Holding both probe tips affects high-value resistors

- Poor contact: Oxidized leads or dirty probes give false readings

- Wrong range: Auto-ranging may be slow or inaccurate

In-Circuit Testing Challenges

Testing resistors without removing them from circuits

Why In-Circuit Testing is Difficult

- Parallel paths: Other components provide alternate current paths

- Active components: Transistors, diodes, ICs affect measurements

- Power rails: Even small voltages can cause errors

- Coupling effects: Capacitors, inductors modify AC test signals

In-Circuit Testing Strategies

Practical Approaches

- Lift one end: Desolder one lead to isolate resistor

- Compare to schematic: Know what resistance to expect

- Use ESR meters: Specialized meters for in-circuit testing

- Functional testing: Verify circuit operation rather than component values

Precision Measurement Techniques

High-accuracy measurements for critical applications

4-Wire (Kelvin) Measurement

Eliminates lead resistance errors by using separate current-carrying and voltage-sensing leads.

R = V_sense / I_force

True resistance using 4-wire method

When to Use Precision Methods

- Low resistance: <1Ω measurements need 4-wire technique

- High accuracy: Better than 0.1% measurements

- Current shunts: Milliohm resistance measurements

- Calibration work: Standards and reference resistors

Common Resistor Failure Modes

How Resistors Fail and Why

Types of Resistor Failures

| Failure Mode | Symptoms | Common Causes | Detection Method | Prevention |

|---|---|---|---|---|

| Open Circuit | Infinite resistance, no current flow | Overcurrent, overheating, mechanical stress | DMM shows OL (overload) | Proper power derating, strain relief |

| Value Drift | Resistance changes over time | Temperature cycling, aging, moisture | Compare to color code or specs | Quality components, controlled environment |

| Thermal Damage | Discoloration, cracking, value change | Excessive power dissipation | Visual inspection, resistance check | Adequate power rating, cooling |

| Physical Damage | Cracks, broken leads, internal breaks | Mechanical stress, vibration, impact | Visual inspection, continuity test | Proper mounting, vibration damping |

| Environmental | Corrosion, contamination effects | Humidity, chemicals, salt spray | Visual inspection, performance test | Conformal coating, sealed packages |

Visual Inspection Guidelines

Color Changes

Brown, black, or dark discoloration indicates overheating. Light color changes may indicate aging or contamination.

Physical Cracks

Hairline cracks in resistor body or coating can indicate thermal stress or mechanical damage.

Lead Corrosion

Green or white deposits on leads indicate corrosion from moisture or chemical exposure.

Heat Damage Signs

Burned PCB traces, discolored nearby components, or melted plastic indicates severe overheating.

Systematic Troubleshooting Approach

Circuit-Level Troubleshooting

Component-Level Analysis

LED Circuit Troubleshooting

Problem: LED not lighting

- Check power: Is voltage present at LED circuit?

- Test LED: Use DMM diode test function

- Check current limiting resistor: Measure resistance value

- Verify connections: Look for broken traces or bad solder

- Calculate expected current: Compare to actual measurement

Advanced Testing Equipment

Professional Test Equipment for Resistors

Specialized Test Instruments

LCR Meters

Measure inductance, capacitance, and resistance

- AC test signals: Multiple frequencies available

- Parasitic measurement: See L and C components

- High accuracy: 0.1% or better capability

- Temperature testing: Some models include temperature chambers

Thermal Testing

Measure temperature coefficient and thermal behavior

- Temperature chambers: Controlled temperature environments

- Thermal cameras: Hot spot identification

- TCR measurement: Precise temperature coefficient determination

- Power cycling: Test thermal stress effects

Noise Testing

Measure electrical noise characteristics

- Current noise: Excess noise beyond thermal noise

- 1/f noise: Low-frequency noise characteristics

- Voltage coefficient: Resistance change with applied voltage

- Audio applications: Critical for high-end audio circuits

Automated Test Equipment (ATE)

Production Testing Capabilities

- High-speed measurement: Thousands of components per hour

- Statistical analysis: Track parameter distributions

- Binning: Sort components by performance grades

- Traceability: Database recording of all measurements

- Standards compliance: Automatic verification against specifications

Troubleshooting Decision Tree

Quick Troubleshooting Guide

Safety Considerations When Working with Resistors

While resistors are generally safe components, proper handling and circuit design practices are essential to prevent injury, component damage, and fire hazards, especially when working with high-power applications or sensitive electronic systems.

Important Safety Warning

HIGH TEMPERATURE HAZARD: Power resistors can reach temperatures exceeding 200°C (392°F) during normal operation. Always allow adequate cooling time before handling, and use appropriate protection when working near hot components.

Power Resistor Safety

Thermal Hazards

High-power resistors generate significant heat

Temperature Safety Guidelines

- Surface temperatures: Can exceed 200°C on high-power resistors

- Burn hazard: Instant burns possible from contact with hot surfaces

- Fire risk: Nearby flammable materials can ignite

- Component damage: Heat can damage adjacent components

Safety Precautions

- Allow 15+ minutes cooling time after power-off

- Use heat-resistant gloves when necessary

- Maintain safe clearances from flammable materials

- Install thermal protection and monitoring systems

- Use proper ventilation and heat sinks

Electrical Safety

High voltages and currents in power circuits

Electrical Hazards

- High voltage: Dangerous voltages across resistors in HV circuits

- High current: Severe burns from high-current paths

- Stored energy: Energy storage in associated reactive components

- Arc flash: Potential for electrical arcing in high-power circuits

Electrical Safety Measures

- Always de-energize circuits before working

- Use lockout/tagout procedures

- Verify zero energy state with meters

- Use appropriate PPE for voltage levels

- Follow arc flash safety protocols

Fire Prevention

Preventing fires from resistor overheating

Fire Risk Factors

- Overload conditions: Excessive current causing overheating

- Component failure: Short circuits or partial failures

- Poor ventilation: Inadequate heat dissipation

- Flammable materials: Paper, plastic, or wood near hot resistors

Fire Prevention Strategies

- Install thermal fuses and protection circuits

- Use flame-retardant materials in enclosures

- Maintain proper clearances and ventilation

- Regular inspection of high-power circuits

- Install smoke detection systems

General Safety Best Practices

- Always derate components: Use conservative power ratings

- Provide adequate cooling: Heat sinks, fans, ventilation

- Use protection circuits: Fuses, circuit breakers, thermal protection

- Regular maintenance: Inspect for signs of overheating or damage

- Proper training: Ensure all personnel understand safety procedures

- Emergency procedures: Know how to safely shut down and evacuate

Frequently Asked Questions about Resistors

Common questions and expert answers about resistors, their applications, and troubleshooting. These FAQs address both beginner and advanced topics to help you understand and work with resistors effectively.

Basic Resistor Questions

Q: What exactly does a resistor do in a circuit?

A: A resistor controls the flow of electric current by providing resistance. Think of it like a valve in a water pipe - it restricts flow and creates a voltage drop. This allows resistors to limit current to safe levels, divide voltages, and convert electrical energy to heat when needed.

Q: Why do resistors have color bands instead of printed numbers?

A: Color bands are used because they're visible from any angle, don't wear off easily, work in all lighting conditions, and can be read even when the resistor is mounted on a circuit board. Numbers might be too small to read on tiny resistors or could be oriented away from view.

Q: Can I use a higher wattage resistor than required?

A: Yes, absolutely! Using a higher wattage resistor is always safe and often recommended. A 1W resistor can handle any load that a 1/4W resistor can, plus much more. The only downsides are slightly larger size and higher cost.

Q: What happens if I use the wrong resistor value?

A: It depends on the application. In an LED circuit, wrong resistance might make the LED too dim, too bright, or damaged. In a digital circuit, it might affect switching speed or noise immunity. Always calculate the correct value using Ohm's Law for your specific application.

Practical Application Questions

Q: How do I choose between 1% and 5% tolerance resistors?

A: Use 1% resistors when circuit performance depends on precise resistance values (like precision voltage dividers, filters, or measurement circuits). Use 5% resistors for general applications like LED current limiting or pull-up resistors where exact values aren't critical. 1% resistors cost about 50% more than 5%.

Q: Why does my resistor get hot?

A: Resistors convert electrical energy to heat energy - this is normal! The heat generated follows P = I²R. If a resistor gets too hot to touch, check: (1) Is the current higher than expected? (2) Is the power rating adequate? (3) Is there proper ventilation? Use a higher wattage resistor or reduce the current if overheating occurs.

Q: Can I connect resistors in series or parallel to get the value I need?

A: Yes! Series connection adds resistances (R_total = R1 + R2), while parallel connection gives 1/R_total = 1/R1 + 1/R2. This is useful when you need a specific value not available in standard series. Just remember that tolerance stacks up, so combined tolerance will be worse than individual resistors.

Q: What's the difference between through-hole and surface mount resistors?

A: Through-hole resistors have wire leads and go through holes in the PCB - easier to handle and replace, better for prototyping. Surface mount (SMD) resistors are tiny, flat components soldered directly to PCB pads - smaller, better for automated assembly, used in modern electronics. Performance is similar, choice depends on application and assembly method.

Troubleshooting and Testing Questions

Q: How do I test if a resistor is good or bad?

A: Use a digital multimeter to measure resistance with power OFF. Compare to the color code value (within tolerance). A good resistor reads close to its rated value. A bad resistor might read infinite (open), zero (shorted), or significantly outside tolerance. Visual signs include discoloration, cracks, or burn marks.

Q: Why does my multimeter show a different value than the color code?

A: Several possibilities: (1) Reading error - double-check color code interpretation, (2) Tolerance - resistor may be within spec but at the edge of tolerance, (3) Meter accuracy - cheap meters have poor accuracy, (4) Test conditions - temperature affects resistance, (5) Parallel paths - other circuit components affecting measurement.

Q: Can I test resistors while they're in the circuit?

A: It's difficult and often inaccurate. Other components create parallel paths that affect readings. For accurate testing, either lift one end of the resistor or remove it completely. Some specialized meters can compensate for parallel effects, but basic multimeters cannot.

Q: My circuit worked before but now doesn't - could it be a resistor?

A: Possible, especially if you see visual damage. Resistors can fail due to overcurrent (open circuit), overheating (value change), or physical damage. Check for discolored or cracked resistors first. Measure critical resistors with a multimeter. However, other components like capacitors and semiconductors fail more often than resistors.

Advanced Technical Questions

Q: What's the difference between metal film and carbon film resistors?

A: Metal film resistors offer better tolerance (±1% vs ±5%), lower temperature coefficient (better stability), lower noise, and better long-term stability. Carbon film resistors are cheaper and adequate for non-critical applications. For precision circuits, audio, or measurement applications, choose metal film.

Q: Do resistors have inductance and capacitance?

A: Yes, all real resistors have parasitic inductance and capacitance, though usually negligible at low frequencies. Wire wound resistors have the most inductance, thin film chip resistors have the least. This matters in RF circuits or high-speed digital applications where these parasitics can affect circuit behavior.

Q: What causes resistor values to drift over time?

A: Several factors: (1) Temperature cycling causes mechanical stress, (2) Moisture absorption affects material properties, (3) Electrical stress from overcurrent/overvoltage, (4) UV exposure degrades some materials, (5) Chemical contamination from flux or environment. High-quality resistors in controlled environments drift less than 1% over years.

Q: Why are precision resistors so expensive?

A: Precision resistors require special materials (like bulk metal foil), tighter manufacturing controls, extensive testing, and lower yields. A ±0.01% resistor might cost 100× more than a ±5% resistor, but for applications requiring that precision (like calibration standards), the cost is justified by performance needs.

Conclusion: The Fundamental Building Block of Electronics

Resistors are truly the fundamental building blocks of electronic circuits. From the simplest LED circuit to the most complex computer processor, resistors play essential roles in controlling current, dividing voltages, and managing power throughout the system.

Key Takeaways from Our Journey

Fundamental Importance

Resistors are present in virtually every electronic device, performing critical functions that enable proper circuit operation and component protection.

Color Code Mastery

Understanding the color code system allows quick identification of resistor values, essential for circuit analysis and troubleshooting.

Ohm's Law Application

The relationship V = IR governs all resistor behavior and is fundamental to understanding how electronic circuits work.

Safety Awareness

Proper power rating selection and thermal management ensure safe operation and prevent component failure or fire hazards.

Knowledge × Practice = Expertise

Your resistor mastery journey starts here!

Thank You for Learning with Power4all!

We hope this comprehensive guide has provided you with valuable insights into the world of resistors. Continue exploring our other guides and resources to expand your electronics knowledge even further.