Inverters in Power Electronics: Types, Working, and Applications

The main role of an inverter is to convert DC into AC, making it possible to power standard appliances from batteries or solar panels.

- What is Inverter ?

- How Does an Inverter Work?

- Main Types of Inverters

- Inverter Output Waveforms

- Inverter Topologies

- Special Types of Inverters

- Single Phase vs. Three Phase Inverters

- Key Applications of Inverters

- Advantages of Modern Inverter Technology

- Frequently Asked Questions About Inverters

- Related Topics

What is Inverter ?

An inverter is an electrical device that transforms direct current (DC) into alternating current (AC). AC power is essential for a wide range of applications in commercial, industrial, and residential settings. However, a significant challenge with AC power is the inability to store it in batteries, which is crucial for providing backup power during outages.

This limitation can be addressed through the utilization of direct current sources. The process involves the conversion of alternating current into direct current (DC) for the purpose of storage. Unlike AC sources, the polarity of DC sources remains constant over time, enabling the storage of DC in batteries and ultra-capacitors. Subsequently, when AC is required to power AC appliances, the DC is converted back into AC. For a deeper understanding of the fundamental variances between AC and DC currents and voltage, it is advisable to consult the previous post on this subject.

Inverters are widely used in various applications, including renewable energy systems, uninterruptible power supplies (UPS), electric vehicles, and motor drives. They play a crucial role in converting and controlling electrical energy for efficient operation.

How Does an Inverter Work?

An inverter works by taking DC power (like from a battery or solar panel) and using electronic switches-such as MOSFETs or IGBTs-to rapidly turn the power on and off. This creates a series of voltage pulses, which are then shaped and filtered to form an AC output. The inverter can also adjust the voltage and frequency of the output, which is especially useful for controlling the speed of motors or matching the requirements of the grid.

- Rectification Stage: If the input is AC (from the grid), it is first converted to DC using a rectifier and smoothing capacitor.

- Switching Stage: Power semiconductor switches chop the DC into pulses. The timing and width of these pulses are controlled by a microcontroller or dedicated circuit.

- Output Filtering: Inductors and capacitors smooth the pulses into a clean AC waveform, suitable for most devices.

- Control: Modern inverters use techniques like PWM (Pulse Width Modulation) to adjust the output for efficiency and stability.

Main Types of Inverters

- Voltage Source Inverter (VSI): Uses a stiff DC voltage as input. This is the most common type, found in home inverters, solar systems, and motor drives. VSIs offer fast response and are easy to control.

- Current Source Inverter (CSI): Uses a constant DC current as input, often with a large inductor. CSIs are used in some industrial drives and applications where current control is more important than voltage control.

Inverter Output Waveforms

- Square Wave Inverter: Produces a simple on/off waveform. Cheap and easy to build, but high in electrical noise (harmonics). Suitable for basic loads like lights or heaters, but not for sensitive electronics.

- Modified Sine Wave Inverter: Creates a stepped approximation of a sine wave. More compatible with a wider range of devices than square wave inverters, but can still cause issues with some electronics and motors.

- Pure Sine Wave Inverter: Delivers a smooth, grid-like AC waveform. Best for sensitive electronics, medical equipment, and anything with a motor or transformer. Pure sine wave inverters are more expensive but provide the highest quality power.

Inverter Topologies

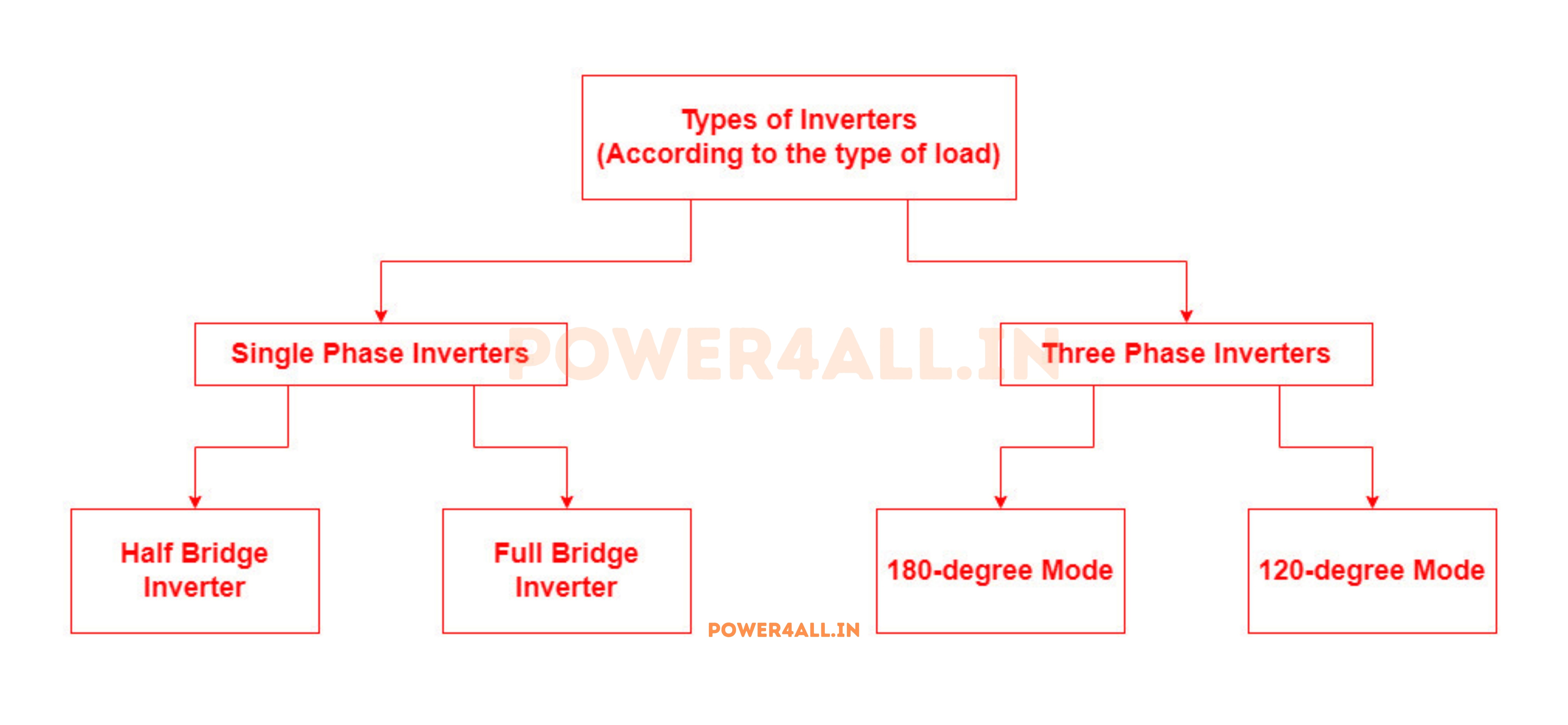

- Half-Bridge Inverter: Uses two switches and produces an output with two voltage levels. It's simple and often used as a building block for more complex circuits.

- Full-Bridge Inverter: Uses four switches to create a more efficient and flexible AC output. This is the standard topology for most single-phase inverters.

- Multilevel Inverter: Uses multiple switches and voltage sources to produce output with several voltage steps, reducing electrical noise and improving efficiency. Types include diode-clamped, flying capacitor, and cascaded H-bridge inverters.

- Parallel and Series Inverters: Designed for specific industrial needs, these topologies can handle higher power or provide redundancy.

Special Types of Inverters

- Grid-Tie Inverter: Connects renewable energy sources (like solar panels) to the utility grid. It matches the grid's voltage and frequency and can feed excess power back to the grid.

- Off-Grid Inverter: Works independently of the utility grid, often with batteries, for backup or remote power systems.

- Hybrid Inverter: Combines grid-tie and off-grid features, automatically switching between modes and managing battery storage.

- Bimodal Inverter: Can operate both with and without the grid, switching modes as needed for backup or grid support.

Single Phase vs. Three Phase Inverters

- Single Phase Inverter: Produces one AC output, commonly used in homes and small businesses for typical appliances and lighting.

- Three Phase Inverter: Produces three AC outputs, each phase shifted by 180 and 120 degrees. Used for industrial motors, heavy machinery, and large-scale solar systems, offering smoother and more efficient power delivery.

Key Applications of Inverters

- Renewable Energy Systems: Solar and wind power conversion for homes, businesses, and grid integration.

- Uninterruptible Power Supplies (UPS): Backup power for computers, hospitals, and critical infrastructure.

- Electric Vehicles: Powering and controlling electric motors.

- Home Appliances: Running refrigerators, air conditioners, and other devices with variable speed and high efficiency.

- Industrial Equipment: Motor drives, pumps, fans, and automation systems.

Advantages of Modern Inverter Technology

- Improved energy efficiency and lower electricity bills.

- Quieter operation and less wear on motors and appliances.

- Stable voltage and frequency for sensitive electronics.

- Better compatibility with renewable energy and smart grids.

- Flexible operation for both grid-connected and standalone systems.